Table of Contents

3D printed lithophane is a one-of-a-kind way to add elegance to your photos. We’ll figure out how to make your 3D Print Lithophane in this article!

What exactly is a 3d Printed Lithophane?

Making photos into 3D objects adds emotion and a new dimension to them. 3D print lithophanes are a simple way to improve your favorite images among the various methods.

Lithophanes are embossed photos produced by a 3D printer. The print results don’t appear to show much at first but shine a light through one, and you’ll be amazed at the details. It works by allowing light to pass through the thin parts while blocking them with the thick parts. The differences in light bring out the image’s details in this way.

Let’s look at making a 3d printed lithophane from a photograph.

How to Make a 3D Print Lithophane Model

There are numerous tools for converting your photo into a 3d printed lithophane model, but they all work in the same way. They begin by guessing and embossing the primary object of the photograph. They then add a nice border and send you the final file in a 3D format such as STL.

You can use Adobe Photoshop CC to create the 3D print lithophane model. However, if you want to keep things simple, you can also use an online tool like the one provided by 3DP Rocks!

3D Printer Lithophane

Method 1- Step 1: Use Photoshop to Create a 3D Print Lithophane Model

Adobe has been adding features to operate with 3D elements in Photoshop since Photoshop CS5. These features are frequently used to transform 2D objects into 3D objects, which will be used by our action set to generate lithophane. To begin, click here to download the “Make lithophane” action set. Drag and drop the .atn file into your Photoshop window to install it once you’ve downloaded it

Then carry out the following steps:

- Open your photo with Photoshop.

- Go to the Window menu and select Actions (or press Alt+F9) to open the actions tool.

- Choose the action from the Make Lithophane folder and press the play button.

Photoshop will now perform a series of actions (adding texture maps, for example) to generate your 3D printing lithophane. When you’re finished, you should be able to see your 3D printed lithophane.

Note that the entire process is based on Photoshop guessing the correct depth based on the contrast difference. As a result, images with higher contrast will most likely produce better results.

Depending on your system specifications, the action will take some time, and Photoshop may become unusable during the process. Be patient and don’t click on anything to avoid the software crashing.

3D Printer Lithophane

Method 1 – Step2: Create an STL File from the 3D Print Lithophane Model.

We need to print your lithophane model now that you’ve designed it. Although Photoshop is capable of 3D printing, we all love to print with our preferred slicers.

Here’s how to export your work:

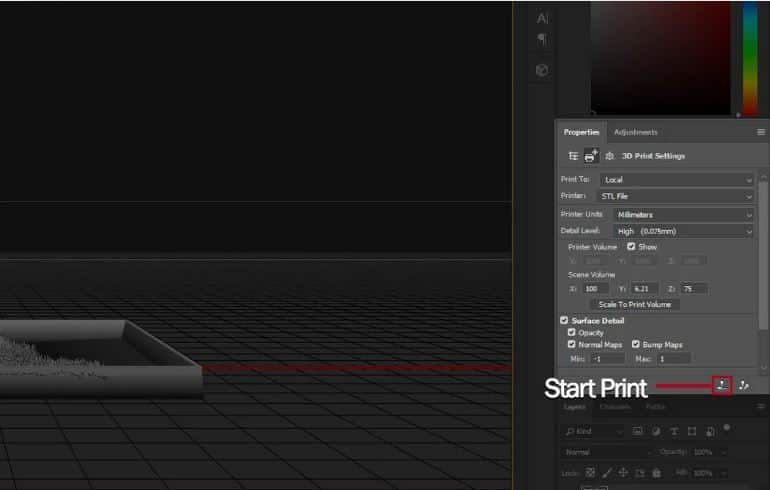

- Select 3D Print Settings from the 3D menu.

- On the right, the Properties tab will appear. Change the “Printers” to “STL File” and then select “Local” from the “Print to” menu.

- Following that, change the printer units to millimeters and increase the detail level to high.

- From the bar below, press the small “Start Print” button.

The export process can also consume a significant amount of memory and, depending on your computer, may cause Photoshop to freeze for a short period. However, your 3D lithophane will be ready in STL format once completed!

3D Printer Lithophane

Method 2: Using 3DP Rocks, Create a 3D Print Lithophane Model

If you don’t want to use Photoshop, here’s an alternative method:

- Proceed to 3DP Rocks.

- Then, select the Images tab and upload your image.

- When you return to the Model tab, you’ll see that your 3d printing lithophane is nearly finished. You can make your 3D printing lithophane into a variety of shapes.

- Adjust the settings until you’re happy with the outcome.

- Finally, in the Model tab, click “Download.”

3D Printer Lithophane

Method 3: Using lithophanemaker.com, Create a 3D Print Lithophane Model

This is another online tool to turn your images into 3d printing lithophane.

- Proceed to the Lithophane Maker website.

- Then, select the type of lithophane on the homepage

- Upload your image or images according to your selected lithophane

- Adjust the settings until you’re happy with the outcome.

- Add your email address

- Finally, click the “Create .stl” button

3D Printer Lithophane

Method 4: Using itslitho.com, Create a 3D Print Lithophane Model

itslitho.com is another online tool that you can turn your images into 3d printing lithophane.

- Proceed to the itslitho.com website.

- Then, click the “GET STARTED” button.

- With the lithophane creator, you may upload one or more photographs. More photographs will be combined into one model if you upload more!

- Use the ItsLitho image editor to make changes to your image. To get the image ready for the design, adjust the contrast.

- Choose the shape you want to use and tweak it to your liking. ItsLitho’s simple sliders will let you create your model.

- You can save your project as an STL file once you’ve done it.

Once you’ve finished downloading the STL file and you’re ready to go!

3D Printer Lithophane

FDM 3D Printing Lithophane

- Printing should be as simple as it is with any other model. There are no additional settings required, but there are a few things to keep in mind:

- If you intend to print your lithophane vertically, keep the layer height as low as possible.

- Do not print at high speeds. Try to keep it under 2000 mm/min because we require all the details.

- Setting the infill to 100% will allow the light to do its job more effectively.

- Avoid using transparent filaments.

3D Printer Lithophane

SLA Lithophane 3D Printing

- On your slicer, 3D print the lithophane. Print the file with the flat side directly on the build platform with no supports for the best results.

- If you intend to print your lithophane vertically, keep the layer height as low as possible.

- Print the file in Standard White Resin at 50 microns for optimum results. Even if you’re pressed for time, 100 microns will produce excellent results.

- Setting the infill to 100% will allow the light to do its job more effectively.

- Avoid using transparent resins.

Conclusion

That’s it! It may appear to be a flat piece of plastic with a few scratches, but hold it up to a light source, such as the sun, and you’ll notice the details.

What is a color lithophane?

Typically, a lithophane is printed with semi-translucent PLA plastic. When light shines through the lithophane, it produces a monochromic image. It means that only one color will be visible, with varying intensities. The light source also must be colored to the photo to add color to the lithophane. Printing the image on a piece of paper or transparent paper will suffice.

Because of the lithophane’s varying thickness, it contains intensity (brightness) information. As a result, if you used the original image, the 3d printed lithophane would look strange. ItsLitho will convert your image into a custom image that you can use to put behind your lithophane. Your original photo, on the other hand, will not work. The picture’s intensity levels have been removed, which results in a very different look on paper. When you put it behind your lithophane, however, it looks great!

Image explicitly created for your color 3d printed lithophane

We’ve spent some time ensuring that the images created by ItsLitho for the color lithophane are the same size as the lithophane you made in the application!

You had to print the picture first and then adjust the lithophane to the picture’s dimensions before using ItsLitho. With ItsLitho, images are now automatically converted to the lithophane’s exact dimensions!

3D Printed Color Lithophane Step-by-Step Instructions

Step 1: Create your 3D printer lithophane first

To begin, use the ItsLitho tool to create your lithophane. In four easy steps, you can make your lithophane:

1. Select the image you want to convert into lithophane from the Upload Image tab;

2. (Optional) Edit image tab – Improve the image’s contrast.

3. Design and tweak your 3D model lithophane in the Create mode tab.

4. Select “Download” from the drop-down menu.

Your lithophane will be created after you press the download button! You’ll get a pop-up when your lithophane is ready to download. You can see how to make lithophane in the video below.

Step 2: Save your files to your computer.

You’ll need two files to make a color lithophane (see video below)

1. Download the lithophane STL file by pressing the lithophane button or the lithophane + attributes button if you’ve added attributes like a nightlight.

2. Press the color lithophane button to download your custom image. You’ve uploaded the photo (s) that will be scaled to the proper dimensions and brightness levels.

Step 3: Make a printout of your documents.

We recommend Esun Cool White PLA PRO for the best color lithophane. This filament has also been used for all of our other color lithophanes, and it is one of the best filaments for lithophanes.

After downloading, you’ll have two file types. These files must be printed in a specific way:

1. 3D print your STL model lithophane; 2. 2D print the custom JPG image on paper (any regular 2D printer will suffice). This can be done with regular paper, but the transparent paper also works!

Now is the time for us to pay attention. The lithophane you made with the tool has exact dimensions in the jpg file. Many programs will attempt to fit your jpg onto an entire A4 sheet of paper. This is something we don’t want! To 2D print with the exact dimensions of your jpg file, we recommend the technique below.

Step 4: Using Paint, create a 2D print of your custom jpg

Paint, to be precise. Paint has a feature that allows us to keep the image’s dimensions. Another advantage is that almost everyone’s computer comes with Paint pre-installed. These settings are highlighted in the image below!

1. In Paint, open the custom-made JPG image you downloaded;

2. Go to the File menu in the top left corner of Paint when it opens;

3. Select Printing;

4. After that, you’ll need to set up your page.

5. Change the Scaling setting to 100 percent of the original size;

6. Print your one-of-a-kind image!

The Scaling setting is the only one you should change. After you’ve set it to 100%, the image will be ready to print and will be the correct size for color lithophane.

Step 5: Attach the custom-made image to the 3D printed lithophane’s backside.

When both prints are finished, we’ll need to do one more thing to make the light shine through the lithophane in vibrant colors.

All we have to do now is adhere the custom-made image to the back of the lithophane. Make sure it’s properly aligned; that’s all there is to it! It’s best not to use liquid adhesives to adhere the paper to the back because it will make the paper wet, and the colors will bleed through. We’ve had a lot of success with inexpensive and straightforward transparent adhesive tape.

You’re ready to make your color lithophane now!

A quick aside

If a plane, arc, or cylinder lithophane is selected, the color image will only export to the correct dimensions. Because spherical lithophane distorts images, it is impossible to map a flat sheet of paper onto a sphere without cutting it.

Results

The color lithophanes we created were a hit! Thanks to the Itslitho Lithophane maker, you can now easily design them yourself! Adding color to the lithophanes is a new and exciting way to spice things up.

The Short History of Lithophane

In the 1820s, Europe was the first to develop modern lithophanes. Their name is derived from the Greek words litho and phainen, which indicate “to bring into being.” In 1827, a Frenchman named Paul de Bourging invented the first method for creating lithophanes, which he termed email ombrant. In 1828, a British man named Robert Griffith Jones purchased the right to manufacture lithophanes and offered production licenses to English companies. Hundreds of thousands of lithophanes were produced in Europe and the United States during the 1800s. Some experts believe the notion originated in China during the Tang or Ming dynasties; however, no lithophane plaque has ever been made in China before 1800.

The earliest lithophanes were the carving an image into wax, forming a plaster gypsum (or sometimes metal) mold from the resin, and casting porcelain at 2000 degrees C. During this technique, porcelain lithophanes would frequently break due to heat pressures, and final lithophanes were typically 1.5 to 6mm thick. Because of these features, lithophane manufacture was labor-intensive, hazardous, and costly. Religion, portraits, literature, and artistic masterpieces were all common scenarios. Lithophanes were used in anything from decorations to fine ceramics to the bottoms of beer steins (to let you know when to refill).

The introduction of new manufacturing technologies has made lithophanes easier to produce. CNC machining in the early 1900s made it possible to carve lithophanes out of translucent, nonporous materials. The dangers of making lithophane were considerably reduced as a result of this. The most frequent method of producing lithophanes nowadays is to 3D print them out of plastic or resin. Although the 3D printing method is inherently complex, it can make beautiful lithophanes for a fraction of the cost of casting or CNC machining. 3D-printed lithophanes may be equipped with a backlight interface, allowing the picture to be seen.

Featured Image: YouTube – RetromanIE