The most widely used 3D printer firmware is Marlin. Learn all the benefits of using it with your desktop 3D printer.

For FDM 3D printers, CNC machines, laser cutters, pen plotters, and a few other devices, Marlin is open-source firmware. It is free for anyone to use and modify under the terms of the GPLv3 license. It is owned and maintained by the community.

Marlin was first released as a standalone product in 2011, and it has its roots in the RepRap community. Since then, Marlin has steadily expanded within the 3D printing industry and is probably the most well-known firmware among amateur and high-end FDM 3D printers.

This article will cover seven reasons why Marlin firmware is so well-liked and why it ought to be a top contender for powering your 3D printer.

Hardware Simplicity

Practicality is one of Marlin’s core values due to its involvement with the RepRap project. In this case, simplicity is frequently advantageous, and a 3D printer with fewer parts and components will be less expensive and simpler to maintain.

A few types of 3D printer firmware require additional hardware or programs to carry out their fundamental functions. Due to the current shortage of electronic components and the high cost of this board, Klipper always requires an additional Raspberry Pi board to pair the RepRap firmware with host software.

Marlin is one of the lightest firmware in this regard. Only one control board is needed in terms of hardware, which is the printer’s mainboard (both 8-bit and 32-bit).

Marlin can get by by using its Autostart feature in operation, whereas most 3D printers have a display for at least starting the 3D printing jobs. Even though using a display to operate your 3D printer is more convenient, you can manage your machine without one.

Well Documented

For non-software engineers, configuring and customizing 3D printing firmware can be somewhat intimidating due to its complexity and intricacy. Although open-source firmware is well-documented, this documentation is frequently done from a development perspective.

The end-user must comprehend at least the high code level and make subtle configurations to suit particular needs to take advantage of all the customization and flexibility associated with open-source 3D printing.

Here, Marlin does a great job of adding more plain-language documentation. The firmware configuration information is comprehensive, extremely detailed, and understandable.

Easy Implementation

Our desktop 3D printers’ firmware is often referred to as the brains of the device. The printers are a collection of parts held together by screws without firmware.

But compared to a heart transplant, installing or replacing the firmware on your printer is much simpler. With Marlin, it’s even easier because it typically just requires flashing the new or updated firmware into the mainboard of the 3D printer.

While it’s true that some vintage 8-bit mainboards may require firmware flashing techniques that resemble open-heart surgery, the majority of modern boards allow for this to be accomplished with a USB connection to a PC or even an SD card that has the firmware file already loaded on it.

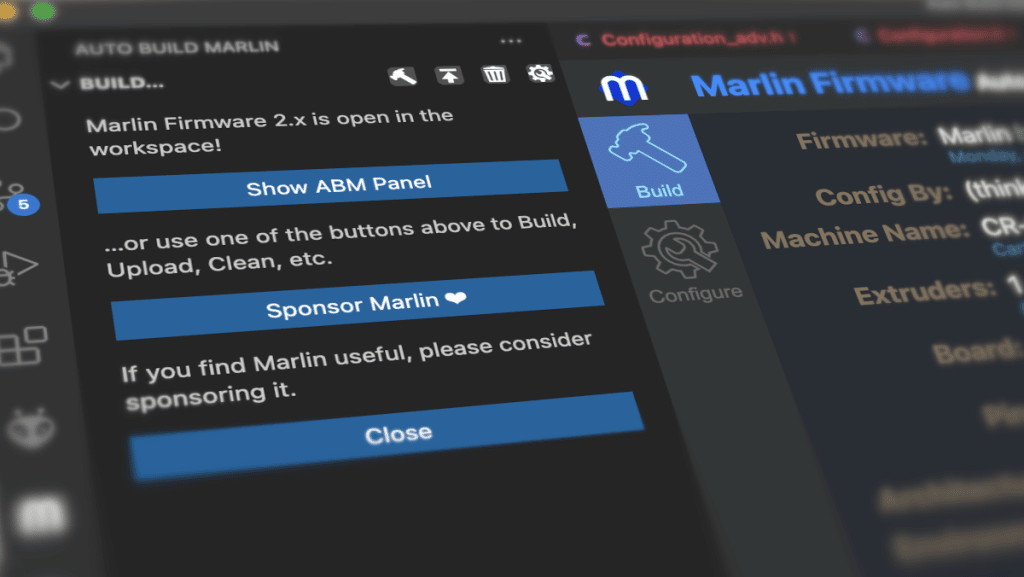

Typically, Arduino IDE or, for 32-bit boards, PlatformIO coupled with VSCode is the software used to compile and flash Marlin via a USB connection. Both programs are free and have a wealth of online tutorials (including Marlin’s guide).

The procedure is more straightforward if you’re fortunate enough to find dependable, pre-configured, and already-compiled firmware that works with your 3D printer.

Improved Safety

Incorrect upkeep and use of 3D printers can make them dangerous devices. They deal with high hot-end temperatures and high electrical currents for heated beds, which could pose a fire risk. Like in the picture above, you’ve probably heard of some 3D printers catching fire.

Even though there are rare instances where several factors result in accidents, we must always exercise caution when using FDM 3D printers. Marlin firmware has some features to track and stop electrical problems.

The most prominent feature is thermal runway detection, a complex system regulating the hot-end nozzle’s thermal progress and bed temperatures. These safeguards keep an eye on the heating elements and turn them off automatically whenever something goes wrong, terminating the 3D printing job and alerting the user.

But remember that you should ensure the firmware has these features enabled. For instance, thermal runaway detection defaulted disabled when Anet A8 printers (with a Marlin fork) were shipped. This may have prevented many of the fire hazards associated with these devices.

Also, be aware that even though they add a level of security, these Marlin features alone cannot ensure the total safety of your 3D printing operation.

Flexibility

The world of 3D printing is diverse. The possibilities for how printers move the printhead and extrude material are vast, even in the constrained environment of desktop FDM 3D printing.

Due to its high degree of customization, Marlin firmware enables users to make significant and minor hardware changes quickly. Marlin has you covered if you’re considering a complete upgrade for your printer, including extra extruders, sensorless homing, speed-controlled fans, and the whole nine yards.

The entire Marlin firmware must be updated to reflect these changes, but as we’ve already discussed, Marlin simplifies this process.

Marlin’s flexibility helps more experienced makers build their 3D printers from the ground up because it supports a variety of 3D printer designs, including Cartesian, Delta, CoreXY, and others.

Even further, Marlin can operate small CNC and laser cutting and engraving machines. This way, one can configure and customize various devices using the knowledge gained from tinkering with 3D printing firmware.

Reliability

The reason for Marlin’s enormous following and ongoing presence in the commercial 3D printing industry is that it is incredibly trustworthy.

Reliability matters when money and effort are invested in 3D printing projects, regardless of whether you’re a business using the technology for commercial purposes or a maker building your projects for enjoyment.

No business wants to delay a service or a product because of broken machinery or sporadic print failures. Considering the waste of filament, energy, and machine time, it isn’t good for business and is expensive.

This is also true for makers and hobbyists: Imagine how frustrating it would be to find out that your 20-plus-hour print job had failed right before the finish line due to a firmware problem.

Not that Marlin is without flaws or bugs; many of them exist. However, given how long Marlin has been used in the 3D printing industry and how many businesses use it in their print farms to produce goods daily, you can get a hint about its dependability from this.

Regular Updates

Not least, but equally important, we must discuss updates. No matter how strong and practical, the software is useless if it isn’t regularly updated and maintained. Marlin has a lot to offer in this regard as well.

From v2.0.9.3 to v2.1.1, there have been five updates in 2022 alone, with each minor change duly documented at Marlin’s GitHub repository.

New features, enhancements, bug fixes, newly supported mainboards, LCD updates, and other improvements are included in every new Marlin release.

This also demonstrates the level of activity of the Marlin open-source development team, so we can be confident that the Marlin project and firmware will likely outlive our current 3D printing systems.

Download Marlin: https://marlinfw.org/meta/download/

What other benefits does the Marlin have?

Let us know in the comments below or on our Facebook page to let us know your ideas, and we would appreciate seeing pictures of your works of art!