Introduction

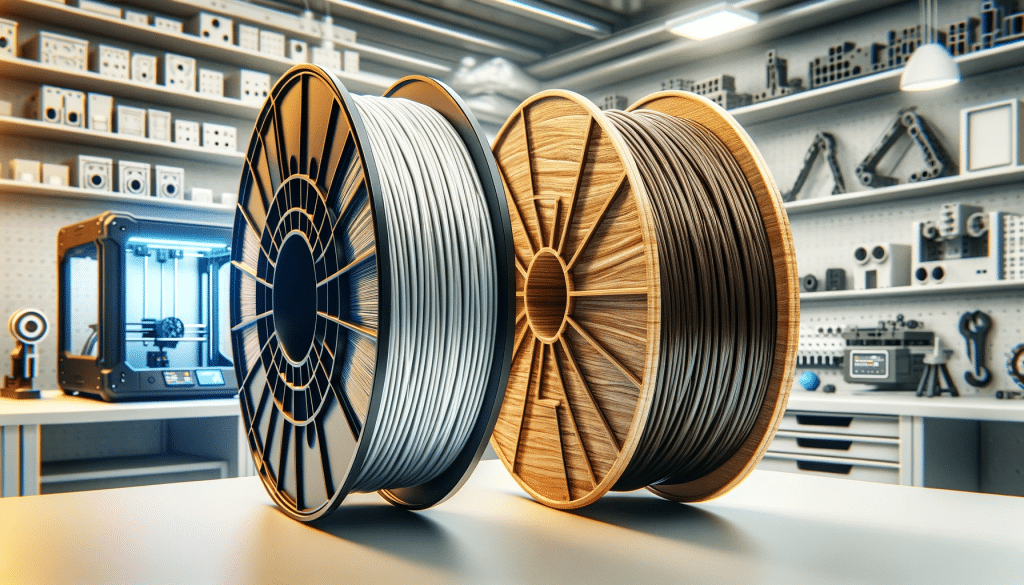

3D printing, a cornerstone of modern fabrication, offers a myriad of possibilities with various materials. Among these, PLA (Polylactic Acid) and PETG (Polyethylene Terephthalate Glycol) are two prominent filaments, each with unique characteristics and applications. Understanding the nuances of PETG vs PLA is crucial for makers, hobbyists, and professionals to make informed decisions. This article aims to demystify these popular filaments, helping you to choose the right material for your next 3D printing project.

The world of 3D printing materials is vast, but PLA and PETG have emerged as favorites due to their distinct properties and ease of use. Whether you’re creating intricate models, functional prototypes, or durable parts, selecting the right filament can significantly impact the outcome of your print. Let’s dive deeper into what makes these materials stand apart and when to use each.PETG vs PLA, understanding their distinct characteristics is crucial for optimal use. Let’s delve into the world of these filaments to determine which is best suited for your specific 3D printing needs.

What is PLA?

PLA, or Polylactic Acid, is more than just a filament; it represents a sustainable approach to 3D printing. Derived from renewable resources like corn starch or sugarcane, PLA is celebrated for its biodegradability and eco-friendly profile. Its lower melting point makes it a go-to choice for a wide range of printing applications, especially in educational and decorative contexts. PLA’s popularity stems not only from its environmental benefits but also from its ease of printing, making it a staple in the 3D printing community.

However, PLA’s use extends beyond its ecological advantages. Its ability to print detailed models with a high degree of precision makes it ideal for artists and hobbyists. The filament’s variety in colors and finishes allows for the creation of visually stunning pieces, from intricate jewelry to complex architectural models. PLA’s versatility is a testament to its widespread adoption in both amateur and professional settings.

What is PETG?

PLA, or Polylactic Acid, is more than just a filament; it represents a sustainable approach to 3D printing. Derived from renewable resources like corn starch or sugarcane, PLA is celebrated for its biodegradability and eco-friendly profile. Its lower melting point makes it a go-to choice for a wide range of printing applications, especially in educational and decorative contexts. PLA’s popularity stems not only from its environmental benefits but also from its ease of printing, making it a staple in the 3D printing community.

However, PLA’s use extends beyond its ecological advantages. Its ability to print detailed models with a high degree of precision makes it ideal for artists and hobbyists. The filament’s variety in colors and finishes allows for the creation of visually stunning pieces, from intricate jewelry to complex architectural models. PLA’s versatility is a testament to its widespread adoption in both amateur and professional settings.

Advantages of PLA

PLA’s ease of printing is a major advantage, especially for those new to 3D printing. It does not require a heated bed, reducing the complexity and cost of the printing setup. This material also exhibits minimal warping, making it more forgiving during the printing process. Its lower printing temperature means less energy consumption, aligning with its eco-friendly nature.

In addition to its user-friendliness, PLA is celebrated for its environmental benefits. As a biodegradable material, PLA represents a responsible choice for those conscious of their ecological footprint. This aspect, combined with its versatility in applications, makes PLA an ideal material for creating everything from artistic sculptures to functional household items. Its wide range of colors and finishes further enhances its appeal, offering creative freedom for designers and hobbyists.

- Ease of Printing: PLA prints at lower temperatures and does not require a heated bed, making it more user-friendly.

- Eco-Friendly: As a biodegradable material made from natural resources, PLA is a greener choice.

- Versatile Applications: Ideal for a wide range of printing projects, including models, prototypes, and educational tools.

Advantages of PETG

PETG’s superior durability is its standout feature. This filament is capable of producing parts that can endure more stress and strain than those made with PLA. Its flexibility, combined with its strength, makes it ideal for parts that require a degree of resilience, such as hinges or protective components. PETG’s resistance to chemicals and heat further enhances its suitability for practical applications in challenging environments.

Beyond its robustness, PETG is known for its print quality. It can produce prints with a glossy finish and excellent layer adhesion, resulting in objects that are not only strong but also aesthetically pleasing. This makes PETG an excellent choice for functional objects that need to maintain a professional, high-quality appearance, like custom enclosures for electronics or durable outdoor signage.

- Durability: PETG offers superior strength and flexibility, which is essential for functional parts.

- Chemical and Heat Resistance: Makes it suitable for outdoor and industrial applications.

- Print Quality: PETG can produce prints with a glossy finish and excellent layer adhesion.

Comparative Analysis: PETG vs PLA

| Feature | PLA | PETG |

|---|---|---|

| Durability | Good | Excellent |

| Flexibility | Moderate | High |

| Print Temp | Lower (180-220°C) | Higher (220-250°C) |

| Ease of Use | Easier, great for beginners | Requires more fine-tuning |

| Finish | Matte | Glossy |

The choice between PETG and PLA often comes down to a trade-off between ease of use and functional strength. PLA’s lower printing temperature and minimal warping make it a more forgiving material, especially for beginners or those working on detailed, decorative projects. Its matte finish gives a unique aesthetic that suits artistic creations. However, PLA lacks the strength and flexibility of PETG, making it less suitable for functional parts or items exposed to harsh conditions.

PETG, on the other hand, requires a bit more skill to print correctly due to its higher printing temperature and potential for stringing. But the effort is rewarded with parts that are significantly stronger and more resilient. PETG’s glossy finish and excellent layer adhesion not only contribute to the strength of the printed object but also give it a professional, high-quality look. This makes PETG a preferred choice for applications where durability and appearance are equally important.

When to Use PLA

PLA is the filament of choice when ease of printing, environmental sustainability, and aesthetics are key considerations. Its wide range of colors and finishes makes it ideal for visually appealing projects like models, toys, and decorative items. PLA’s low melting point and ease of use make it particularly suitable for educational environments, where safety and simplicity are paramount.

However, the versatility of PLA extends beyond simple projects. It is also well-suited for prototyping designs where detail and precision are more critical than functional strength. PLA prints can be easily sanded and painted, making it a popular choice for custom art pieces, cosplay items, and intricate architectural models. The eco-friendly nature of PLA also makes it a responsible choice for those looking to minimize their environmental impact.

- Ideal for Beginners: Due to its ease of use and low printing temperature.

- Decorative Items: Perfect for non-functional objects like figurines and cosplay elements.

- Educational Projects: Safe and easy to handle for classroom settings.

- Learn More About PLA

When to Use PETG

Choose PETG for projects that require durability, flexibility, and resistance to environmental factors. This filament is ideal for functional parts such as mechanical components, enclosures, and items that will be exposed to outdoor conditions. PETG’s resilience makes it suitable for applications where parts need to withstand stress, strain, or exposure to chemicals.

PETG is also valuable in prototyping and manufacturing settings where its strength and durability can be leveraged to create parts that closely mimic the final product. Its ability to produce high-quality, glossy finishes makes it a good choice for objects that need to be both strong and aesthetically pleasing. While PETG may require more tuning and expertise to print correctly, its properties make it an invaluable material for advanced 3D printing applications.

- Functional Parts: Excellent for parts subjected to stress, like mechanical components.

- Outdoor Use: Its resistance to elements makes it suitable for outdoor applications.

- Prototyping: Ideal for testing designs under real-world conditions.

- Explore PETG Uses

Tips for Printing with PLA

To achieve the best results with PLA, finding the optimal printing temperature is crucial – usually between 190-220°C. Ensuring good bed adhesion is also important, and while PLA doesn’t require a heated bed, using blue painter’s tape, hairspray, or a glue stick can help prevent warping and ensure a smooth first layer. It’s also important to properly calibrate the printer for PLA, as incorrect settings can lead to common issues like stringing or poor layer adhesion.

Another aspect to consider is PLA’s sensitivity to moisture. Storing PLA filament correctly is essential to maintain its print quality. Dry boxes or sealed bags with desiccants can prevent the filament from absorbing moisture from the air, which can cause issues during printing, such as bubbling or poor layer adhesion. Regular maintenance of the printer, including cleaning the nozzle and ensuring the bed is level, will also help achieve the best results with PLA.

- Optimal Temperature: Printing around 190-220°C usually yields the best results.

- Bed Adhesion: A heated bed is not necessary, but using blue painter’s tape or glue stick can help.

- Dealing with Stringing: Retraction settings can be adjusted to minimize stringing issues.

- Perfecting PLA Printing

Tips for Printing with PETG

Printing with PETG requires attention to temperature settings. The ideal printing temperature range for PETG is between 230-250°C, with a heated bed temperature of around 70-85°C. This helps in achieving strong layer adhesion and reducing warping. It’s also crucial to adjust the retraction settings to prevent stringing, a common issue with PETG due to its sticky nature.

PETG adheres well to various build surfaces, but it’s important to avoid using materials like PEI or glass without a release agent, as PETG can stick too well and damage the bed. Applying a thin layer of glue stick or hairspray can help with this. Additionally, PETG benefits from slower print speeds and higher flow rates, which contribute to stronger prints with better layer bonding. Fine-tuning these settings can significantly improve the quality and strength of PETG prints.

- Temperature Settings: Ideal printing temperatures are between 230-250°C.

- Bed Preparation: Using a heated bed with a temperature of around 70-85°C is recommended.

- Preventing Stringing: Fine-tune retraction settings and print speed for cleaner prints.

- PETG Printing Guide

Painting and Smoothing Techniques for PLA and PETG

- Post-Processing: Both materials can be sanded and painted for enhanced aesthetics.

- PLA Smoothing: Can be smoothed using various techniques, including chemical smoothing with solvents.

- PETG Finishing: While tougher to smooth than PLA, a combination of sanding and painting can yield great results.

- Smoothing Techniques, Painting 3D Prints

Environmental Considerations

- PLA’s Biodegradability: PLA is compostable under industrial conditions, offering an environmentally friendly option.

- PETG’s Recyclability: While not biodegradable, PETG can be recycled, making it a sustainable choice for eco-conscious users.

Cost Comparison: PLA vs PETG

- PLA Affordability: Generally cheaper and more accessible, PLA is a cost-effective option for many projects.

- PETG Pricing: Slightly more expensive than PLA, but its durability can provide better value for specific applications.

Conclusion

Choosing between PETG and PLA depends on the specific requirements of your project. PLA is ideal for beginners and for projects that require ease of use and a lower environmental impact. PETG, with its strength and resistance to environmental factors, is better suited for functional parts and applications where durability is key. Both materials have their unique advantages, and understanding their properties will guide you to the right choice for your 3D printing needs.

Key Takeaways

- PLA: Eco-friendly, easy to use, ideal for non-functional items.

- PETG: Durable, chemical and UV resistant, suited for functional parts.

FAQ Section

- Can PETG be used for outdoor projects? Yes, PETG’s UV and moisture resistance make it suitable for outdoor use.

- Is PLA safe for food-related items? PLA is generally considered safe, but it’s not FDA-approved for food contact unless specified.

- How does print speed differ between PLA and PETG? PLA can be printed faster due to its lower melting temperature, while PETG may require slower speeds for better adhesion and finish.

- Can PETG be recycled? Yes, PETG is recyclable, though it should be separated from other plastics due to its specific recycling requirements.

- Is a heated bed necessary for printing with PLA? No, PLA can be printed without a heated bed, although using one can improve adhesion and reduce warping.

By understanding the distinct characteristics of PLA and PETG, you can optimize your 3D printing experience, ensuring that your projects not only look great but also perform well under the conditions they are designed for.