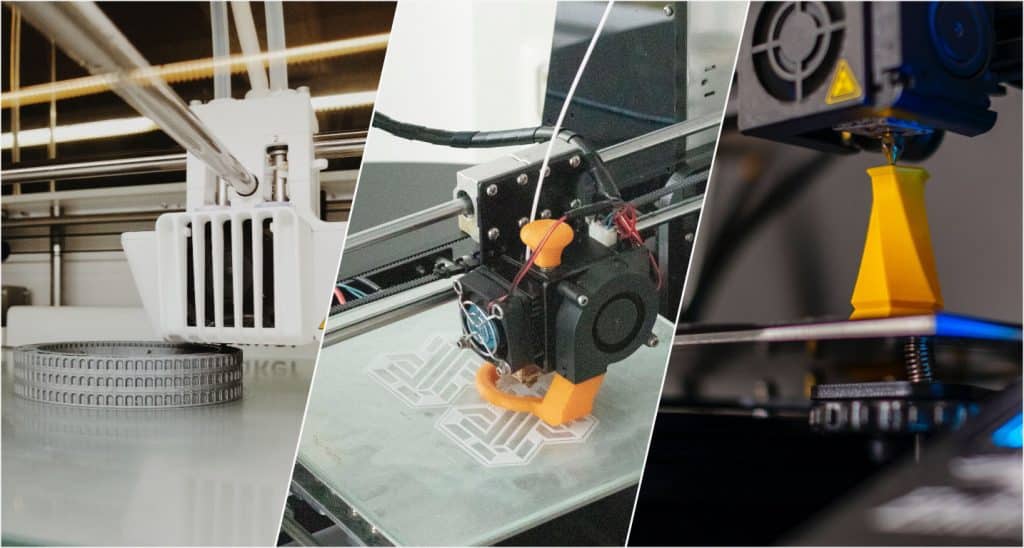

Entering the world of 3D printing can be an exciting and rewarding experience, but it can also be intimidating for beginners. To help you get started on the right foot, we’ve compiled our top 10 essential tips for 3D printing beginners. Follow these tips to improve your 3D printing quality and enjoy a smoother journey into this fascinating world.

The Basics

1. Proper bed leveling

One of the most important aspects of achieving high-quality prints is proper bed leveling. A well-leveled bed ensures that your first layer sticks to the surface evenly, reducing the risk of print failure. To level your bed, follow the instructions provided by your printer’s manufacturer, and don’t be afraid to ask for help on online forums like Reddit’s 3D printing community.

2. Material selection

There are numerous materials available for 3D printing, each with its own set of properties and requirements. To start, we recommend using PLA filament, as it is easy to work with, environmentally friendly, and widely available. As you gain experience, you can experiment with other materials like PETG or ABS.

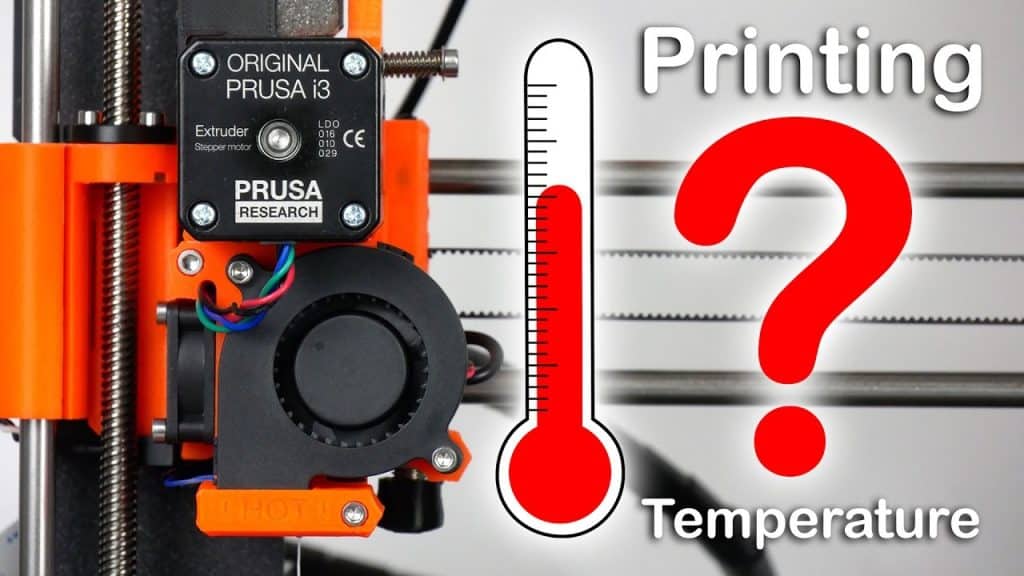

3. Temperature settings

Understanding the optimal temperature settings for both your extruder and bed is crucial for successful 3D printing. Check the manufacturer’s recommendations for your specific filament and adjust accordingly. For instance, the best PLA temperature varies depending on the brand, so make sure to follow their guidelines.

Advanced Techniques

4. Slicer settings

Slicer software is essential for turning your 3D model into a printable file. There are many slicers available, such as Cura, Simplify3D, and PrusaSlicer. Familiarize yourself with your chosen slicer and experiment with different settings to achieve the best results.

5. Infill and support structures

Infill and support structures can significantly impact the quality and strength of your 3D prints. Adjusting infill patterns and densities can help improve the structural integrity of your prints. When it comes to support structures, programs like Simplify3D make it easy to customize and optimize support placement.

6. Post-processing techniques

Troubleshooting common issues in 3D printing is an essential part of the learning process for both beginners and experienced users. Some frequent problems include bed adhesion issues, warping, stringing, and inconsistent extrusion. To resolve these issues, it’s crucial to understand the underlying causes and make appropriate adjustments to your printer settings, slicer software, or printing environment.

Don’t be afraid to seek help from online communities, forums, or manufacturer support, as they can provide valuable guidance and solutions. Remember that patience and persistence are key when working through 3D printing challenges, and with time and practice, you’ll become more adept at producing high-quality prints.

Choosing the Right Materials and Settings

6. Select the right filament

Selecting the right filament for your project plays a crucial role in the quality of your final print. Among the most common filaments are PLA, ABS, PETG, and TPU. Each has its own strengths and weaknesses, which should be considered based on your project requirements. For instance, PLA is easy to print with and biodegradable, but may not be suitable for high-temperature applications. PETG is a good middle ground between PLA and ABS, offering durability and ease of use.

7. Optimal temperature settings

Using the correct temperature settings for your chosen filament is crucial. The hotend temperature, bed temperature, and ambient temperature all play a part in achieving high-quality prints. For instance, PLA requires a lower temperature compared to ABS, and the ideal temperature varies between different brands. Make sure to consult the manufacturer’s guidelines for optimal temperature settings and test various settings to see what works best for you.

8. Slicer settings

Proper slicer settings are essential for high-quality prints. Experiment with various settings in your preferred slicing software, such as layer height, infill percentage, and print speed. For instance, you can achieve a smoother finish by using a lower layer height, but this will increase print time. Remember, your slicer settings will impact not only the print quality but also the strength and weight of the final product.

Post-Processing and Maintenance

9. Post-processing techniques

Once your print is complete, post-processing can significantly improve its appearance. Techniques like sanding, painting, or applying a clear coat can enhance the look of your 3D printed object. For resin prints, make sure to properly clean and cure the object for optimal results. Check out our overview of 3D printing post-processing techniques to learn more.

10. Regular maintenance

Finally, to consistently achieve high-quality prints, it’s essential to perform regular maintenance on your 3D printer. This includes cleaning the printer bed, checking the nozzle for clogs, tightening belts, and lubricating moving parts. Consult our guide on maximizing your 3D printing experience with maintenance tips for detailed instructions.

Frequently Asked Questions

In conclusion, the world of 3D printing is filled with exciting possibilities, but it’s crucial for beginners to have a strong foundation in essential techniques to ensure success. By following these top 10 tips, you’ll be well on your way to achieving high-quality prints and making the most of your 3D printing experience. Remember that patience, practice, and continuous learning are key components of becoming a 3D printing master.

Ready to take your 3D printing skills to the next level? Don’t stop here! We have even more resources, tutorials, and expert advice available to help you continue your journey towards 3D printing mastery. Subscribe to our newsletter and stay up-to-date with the latest innovations, techniques, and tips in the 3D printing world. Click the button below to subscribe now and unlock your full potential in the realm of 3D printing!