Table of Contents

As technology advances, it continues to redefine various sectors of our daily lives, with 3D printing standing out as a remarkable innovation. 3D printing, also known as additive manufacturing, is transforming industries from medicine to automotive, reimagining design processes, and democratizing the creation of objects. In this article, we will explore how to print in 3D, its benefits, applications, and the future it holds.

A Beginner’s Guide to Print in 3D

To print in 3D, it begins with a concept. This concept is then translated into a 3D model using computer-aided design (CAD) software. This model is sliced into layers by a 3D printer slicer, which then converts the model into G-code, a language that the 3D printer understands. Following these instructions, the printer deposits layers of material—ranging from plastic to metal to resin—onto a platform, gradually building up the object until it’s fully formed.

The process to print in 3D may sound complex, but with the right resources and a basic understanding of design software, anyone can start to bring their ideas to life.

Advantages of 3D Printing

3D printing offers a multitude of advantages over traditional manufacturing methods. Here are just a few:

- Rapid Prototyping: 3D printing allows for quicker and more cost-effective prototype creation, helping businesses speed up their product development process.

- Customization: With the ability to print in 3D, unique, tailored products can be created on-demand, without the need for specific molds or cutting tools.

- Reduced Waste: As an additive process, 3D printing only uses the material necessary to create the object, leading to significantly less waste compared to traditional subtractive manufacturing methods.

Real-World Applications: How Industries Print in 3D

The practical applications of 3D printing technology are broad and impactful. Let’s take a deeper look at how various industries are leveraging the ability to print in 3D to transform their operations:

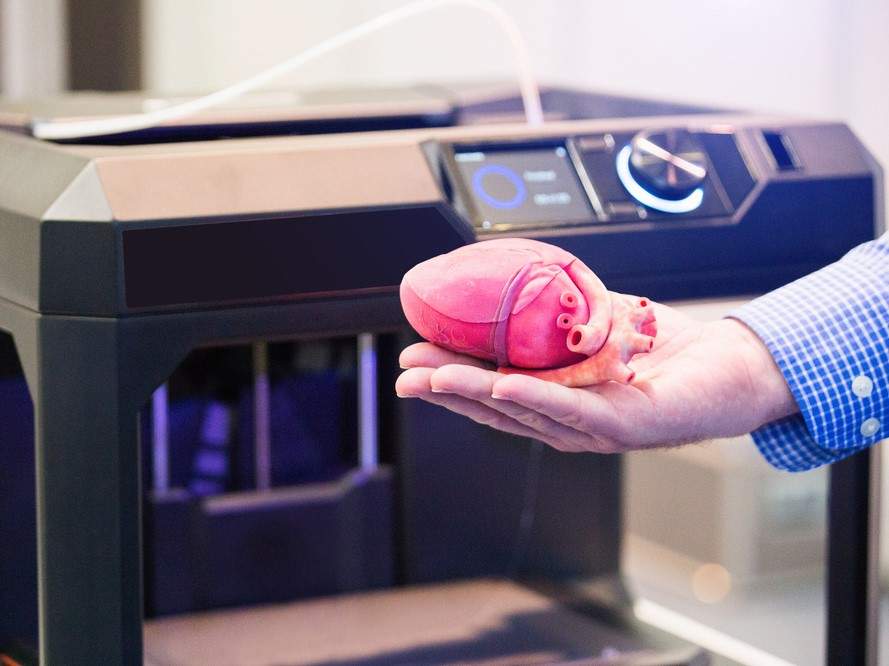

- Medical Industry: 3D printing has revolutionized healthcare in numerous ways. The creation of customized prosthetics and orthotics tailored to each patient’s unique body shape and needs has made these essential devices more comfortable and functional. Medical models of organs, tumors, and other anatomical structures are being 3D printed to aid in surgical preparation, providing doctors with a tangible, detailed reference before they make the first incision. Bioprinting, an exciting area of research, involves printing layers of living cells to form tissues and, potentially, full organs for transplants.

- Dental Industry: In dentistry, 3D printing has become a game-changer. It’s used to create dental implants, braces, aligners, and crowns with unmatched speed and precision. Traditional methods that required molding and casting have been replaced by digital scans and 3D printing, significantly reducing patients’ discomfort and waiting times.

- Automotive and Aerospace: Both the automotive and aerospace industries are using 3D printing to produce lightweight but strong components, test prototypes, and produce parts with complex geometries that would be difficult to manufacture using traditional methods. The ability to print in 3D allows for significant cost savings, quicker production times, and the potential for improved fuel efficiency due to weight reduction.

- Construction: In the construction industry, 3D printing is providing solutions to meet growing housing demand quickly and sustainably. Entire buildings, including residential homes, commercial offices, and even bridges, are being 3D printed. This process can drastically reduce construction times, waste, and costs, and it has the potential to play a significant role in providing affordable housing solutions in the future.

- Fashion and Textile Industry: The fashion industry is also exploring 3D printing. Designers are using this technology to create unique, complex designs that are difficult to achieve using traditional techniques. From intricate jewelry to avant-garde garments and custom footwear, 3D printing is paving the way for a new era of fashion and design.

- Education: In educational settings, 3D printing serves as a practical tool to engage students in STEM subjects. It helps to visualize abstract concepts, enhance creative thinking, and provide hands-on experience with advanced technology. Schools and universities worldwide are incorporating 3D printing into their curriculum, equipping students with skills that are increasingly important in the modern job market.

- Food Industry: An exciting and delicious application of 3D printing lies in the food industry. From 3D printed candy and pasta to intricate cake decorations, and even lab-grown meat, the technology opens up creative and sustainable avenues for food production and presentation.

- Archaeology and Paleontology: 3D printing also aids in the study of our past. Fragile fossils and ancient artifacts can be scanned and 3D printed to allow for closer examination, preservation, and replication. This protects the original items from damage while providing researchers and museums with exact replicas for study and display.

These examples showcase just a fraction of the potential held by 3D printing technology. As it continues to evolve, we can expect even more industries to embrace the ability to print in 3D, changing the way we manufacture, create, learn, and even eat.

Choosing the Right Materials to Print in 3D

Choosing the appropriate material for your 3D print is pivotal to the success of your project. The material you select will influence the print’s durability, flexibility, detail, and even color. Here’s a closer look at some of the most commonly used materials in 3D printing and their distinct characteristics:

- Polylactic Acid (PLA): PLA is an excellent choice for beginners and for projects that do not require high durability or heat resistance. It’s a biodegradable material derived from renewable resources like cornstarch or sugarcane, which makes it an environmentally friendly option. It’s also one of the most user-friendly materials to print in 3D due to its low print temperature and minimal warping.

- Acrylonitrile Butadiene Styrene (ABS): ABS is a petroleum-based plastic that is well-loved for its strength, durability, and high-temperature resistance. This material is commonly used in industrial settings and for creating parts that are intended for long-term use. ABS can be challenging to print with due to its tendency to warp as it cools, but its strong and hardy nature often makes it worth the effort.

- Polyethylene Terephthalate Glycol (PETG): PETG combines the best of PLA and ABS, providing a balance of ease-of-use and durability. It has the strength of ABS but is as easy to print with as PLA, making it an increasingly popular choice among 3D printing enthusiasts. Its ability to withstand moisture also makes it a suitable option for outdoor projects.

- Nylon (Polyamide): Nylon is known for its high strength, flexibility, and durability. It is resistant to impact and abrasion, making it perfect for mechanical parts or items that need to withstand wear and tear. However, nylon can be challenging to print with as it is prone to warping and absorbs moisture from the air, requiring dry storage.

- Resin: Resin is used in Stereolithography (SLA) and Digital Light Processing (DLP) 3D printers. It is ideal for prints requiring high detail and a smooth surface finish, such as jewelry, figurines, and dental models. However, it should be noted that resin printing often requires additional steps for curing and cleaning the print, and the uncured resin can be messy and toxic to handle.

- Flexible Filaments (TPE, TPU): For projects that require a degree of flexibility or rubberiness, like phone cases or seals, flexible filaments such as Thermoplastic Elastomer (TPE) or Thermoplastic Polyurethane (TPU) are ideal. They can be more challenging to print due to their elasticity but offer unique end results that are not achievable with rigid materials.

- Metal: While still a more expensive option mainly used in industrial applications, metal 3D printing is becoming more accessible. Metals such as stainless steel, titanium, and even gold can be 3D printed to produce sturdy, high-performance parts, or unique jewelry pieces.

- Wood Filament: Wood filaments are a mixture of PLA and small wood fibers, which can produce prints with a wood-like appearance, complete with the possibility of wood grain. This filament is a creative choice for decorative items.

Wessex Archaeology’s Studio has its own 3D printer and the skills to both create and prepare digital models for 3D printing. We also have in-house model finishing skills to enhance prints to create realistic replica artefacts and models.

Remember, the key to a successful print in 3D lies not only in a good design but also in choosing the right material. Your choice should align with the specific characteristics and requirements of the project, balancing factors such as durability, detail, flexibility, and the material’s printability.

The Future of 3D Printing

3D printing is not just a disruptive technology of the present, but it’s also shaping the future in numerous ways. Let’s delve deeper into the anticipated trends and advancements that will influence how we print in 3D in the coming years:

- Widespread Adoption: As 3D printers become more affordable and user-friendly, we can expect them to become a common presence not just in industries and schools, but also in households. This democratization of production tools will enable more people to create custom objects at home, from toys and household items to spare parts and tools.

- Metal 3D Printing: Currently, most household 3D printers are limited to using plastic or resin-based materials. However, the future may bring more affordable and accessible metal 3D printers into the mainstream. This would vastly broaden the scope of objects that can be manufactured at home and could revolutionize sectors like automotive and aerospace, where high-strength parts are crucial.

- 3D Bioprinting: The potential for 3D bioprinting is immense. While still in the experimental stage, scientists are making strides in the ability to print organs from living cells. This could solve the organ shortage crisis and save countless lives. In addition to organs, 3D bioprinting may also be used to create skin for burn victims, or to test new medicines without the need for animal testing.

- Artificial Intelligence in 3D Printing: As with many other tech sectors, AI has the potential to significantly influence 3D printing. AI can help optimize designs, improve the print process, and even predict and correct errors before they occur. This could lead to faster print times, less waste, and overall higher quality prints.

- 4D Printing: The concept of 4D printing is a promising future trend. This process involves 3D printing objects with smart materials that can change or adapt their properties over time in response to certain stimuli such as heat, light, or water. While still largely in the research phase, 4D printing could have groundbreaking applications, from self-assembling structures to adaptive clothing or implants.

- Sustainability: With growing environmental concerns, the role of 3D printing in promoting sustainability is also noteworthy. Innovations are being made in the development of eco-friendly printing materials like biodegradable plastics or those made from recycled waste. Furthermore, the ability to produce items locally reduces the carbon footprint associated with transporting goods from overseas.

- Construction: In the future, we might see 3D printed houses becoming more common. As the technology improves, it’s becoming faster and cheaper to build houses using large-scale 3D printers. This could provide solutions for affordable housing and even off-world colonization, with NASA exploring 3D printing for lunar bases.

- Customized Production: The ability to create customized, one-off pieces will continue to reshape industries from healthcare to fashion. Rather than off-the-shelf products, consumers can look forward to items that are tailored to their exact preferences and needs.

The future of 3D printing is, without doubt, bright and exciting. As we continue to understand and explore this technology, the question is not ‘what can we print in 3D?’ but rather ‘what can’t we print in 3D?’ The possibilities are limitless as we embark on this journey of innovation, creativity, and discovery.

Final Thoughts: Print in 3D, Shape the Future

As we’ve explored, to print in 3D is to open up a world of unlimited possibilities. From rapid prototyping to custom manufacturing, 3D printing offers tangible solutions to many of today’s challenges. However, the true power of this technology lies not just in what we can create today, but also in the unimaginable possibilities it holds for the future.

If you’ve ever wondered about how to print in 3D, there’s never been a better time to dive in. Whether you’re a hobbyist wanting to bring your ideas to life, an educator preparing students for the jobs of tomorrow, or a business looking for innovative solutions, understanding how to print in 3D can provide a wealth of opportunities.

Remember, every giant leap for mankind started with a single step. So why not take yours today? Embark on your journey, learn how to print in 3D, and be a part of the revolution shaping the future. The world of 3D printing is vast, fascinating, and waiting for you to explore. Will you take the leap?

Frequently Asked Questions about 3D Printing

1. What is 3D printing?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects from a digital model. This is achieved by laying down successive layers of a specific material until the object is formed.

2. What types of materials can be used to print in 3D?

Various materials can be used in 3D printing, including plastic, resin, metal, nylon, and even biological cells. The choice of material depends on the type of 3D printer being used and the intended application of the final product.

3. How does a 3D printer work?

Most 3D printers work by extruding heated material, typically plastic, through a nozzle that moves precisely under computer control. It prints one layer, waits for it to dry or harden, and then prints another layer on top.

4. Can I print in 3D at home?

Yes, you can. Affordable 3D printers designed for home use have become increasingly popular and accessible. You can use them to create toys, tools, art, decorative items, and even certain types of clothing.

5. How much does a 3D printer cost?

The cost of 3D printers varies widely based on the size, capabilities, and type of printer. As of 2023, you can purchase a basic home 3D printer for as low as a few hundred dollars, while industrial-grade printers can cost thousands or even tens of thousands of dollars.

6. What are the applications of 3D printing?

3D printing has a wide range of applications across numerous industries, from healthcare and education to manufacturing and construction. It is used to make everything from medical prosthetics and architectural models to custom jewelry and aerospace components.

7. What are the benefits of 3D printing?

3D printing offers a multitude of benefits including rapid prototyping, the ability to produce complex geometries, customization, reduced waste, and cost-effectiveness for small production runs.

8. Is 3D printing environmentally friendly?

The impact of 3D printing on the environment can vary. On the one hand, it can lead to less waste produced during the manufacturing process compared to traditional methods. On the other hand, the energy consumption of 3D printers and the type of materials used can affect its environmental footprint. Some 3D printing materials are biodegradable or made from recycled waste, offering more sustainable options.

9. What is the future of 3D printing?

The future of 3D printing looks promising, with advancements in bioprinting, metal 3D printing, artificial intelligence, 4D printing, and more. Widespread adoption of 3D printing is anticipated as the technology becomes more affordable and user-friendly.

10. Is it difficult to learn how to print in 3D?

While there is a learning curve involved, numerous resources, tutorials, and communities are available online to help beginners get started with 3D printing. Furthermore, modern 3D printers and software are becoming increasingly user-friendly.

We hope this deep-dive into 3D printing has sparked your curiosity and broadened your understanding. But the beauty of this innovative technology is that there’s always more to learn, discuss, and explore.

Do you have more questions about how to print in 3D? Or perhaps some insights or experiences to share? We’d love to hear from you. Join the conversation by leaving a comment below. Your input could help other readers embarking on their 3D printing journey.

And if you’d like to stay updated on the latest advancements, tips, and trends in 3D printing, sign up for our newsletter. We’re always exploring the cutting edge of technology, and we’d love to share our discoveries with you. Join our community today and become part of the future of 3D printing!