Table of Contents

Cleaning your build surface is crucial for getting good prints whether you use a glass plate, PEI sheet, or something else! But are you cleaning 3D printer bed efficiently and without harming the bed?

The first printing layer is frequently the most crucial in FDM 3D printing. Many unsuccessful prints result from poor first-layer adhesion, which can be brought on by inaccurate calibration, excessive print speeds, or an improperly prepared build surface.

Keeping the build surface clean is one of the best ways to stop bed adhesion issues. The extruded thermoplastic has a better chance of adhering to a well-maintained surface, and the likelihood of print failure is significantly decreased.

However, it’s not always obvious how to clean the build surface or bed of a 3D printer. Different materials used to create print surfaces have various reactions to specific cleaning agents. The fundamentals of cleaning your 3D print bed are covered in this article, along with the tools you’ll need and the various approaches you can take.

Why is 3D printer bed cleaning important?

The print bed is one of many components that make up an FDM 3D printer, but it is the literal basis for good prints.

The print bed, which creates the printed part, is a stable, flat surface typically made of glass or aluminum. These beds are square or rectangular in Cartesian-style printers and circular in Delta-style printers. The print bed also referred to as a build plate, can be heated or left unheated. A heated bed aids in first-layer adhesion and makes it simpler to remove the finished print.

Confusion arises from not all FDM users using their integrated print bed as their build surface. The print bed itself, as well as other surfaces like a removable glass plate, a rigid plastic sheet, or strips of masking tape, can serve as the build surface, which is the surface where the nozzle deposits the first layer of plastic. Additionally, printer users frequently treat their build surface with additives like glue sticks or hairspray to increase adhesion.

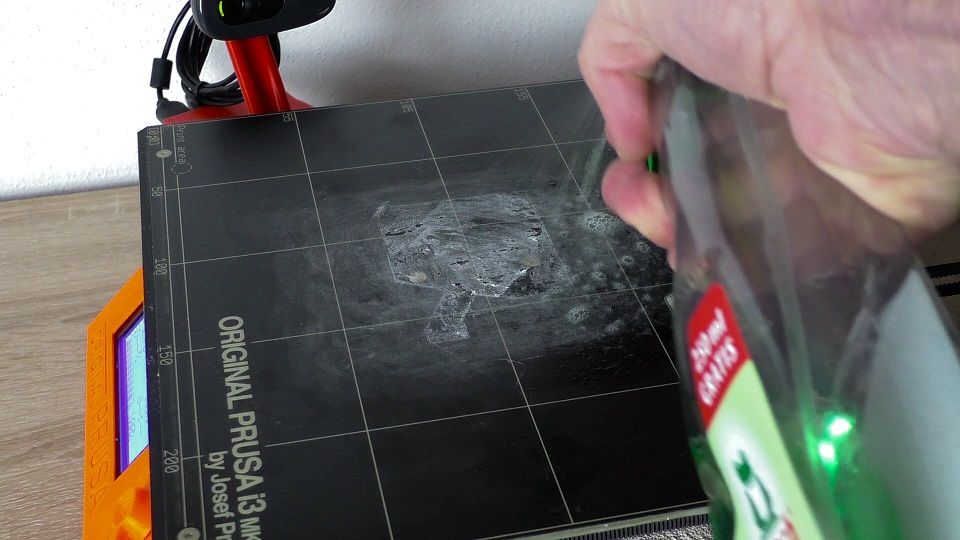

Cleaning the print bed, the build surface, or both may be what we mean when we discuss 3D printer bed cleaning. A dirty build surface with filament buildup can negatively affect adhesion and result in failed prints, so cleaning it is crucial. Even if the print bed is not being used as the build surface, it still needs to be cleaned because doing so will prolong its life and improve its adherence to removable surfaces like tape and BuildTak.

Print bed cleaning supplies

Isopropyl alcohol

Isopropyl alcohol (IPA) is an odorless chemical compound commonly used in antiseptics, detergents, and disinfectants. It sometimes goes by “rubbing alcohol” because it was once used as a topical massage preparation.

IPA, which contains 70–90% alcohol, can be used by FDM users to clean print surfaces like PEI and glass. Although the chemical won’t likely harm these surfaces, it is potent enough to remove grease and residue.

Get the best Isopropyl alcohol (IPA) deals on Amazon.com

Acetone

Acetone is another substance used to clean the build surfaces and beds of 3D printers. Since the solvent can dissolve the plastic (though it won’t cut through PLA), it is also used as a smoothing agent for ABS prints.

Acetone can be used to clean glass beds and is effective at removing some types of plastic filament residue as well as dirt and grease. Although if used too frequently, it can harm a plastic surface. It can also be used to clean PEI and other surfaces.

Window cleaner

A glass surface can be cleaned with a window cleaner. However, window cleaning sprays are designed specifically for cleaning glass so that they can clean glass print beds and surfaces.

In addition to grease-dissolving agents, spray-bottle window cleaners typically contain an alcohol, such as ethanol or isopropanol. They might also include additives, like perfumes, though cleaners for print beds should have fewer additives.

Soap

Ordinary dishwashing soap mixed with warm water is a cheap and effective solution for cleaning print surfaces of various kinds. Unscented products with minimal additives work best.

Equipment

A few pieces of equipment are required, including chemical agents, to clean a printing surface. The following items are helpful to have on hand:

- Scraper: Using a flat-blade scraper to remove residue without harming the print bed or build surface.

- Sandpaper: Sandpaper, which is more abrasive than a scraper or cloth, can assist in maintaining an even surface.

- Cloth: The print bed or build surface can be treated with various substances by applying them with a soft microfiber cloth.

- Paper towels: Use paper towels to apply gentle cleaning solutions like soapy water and window cleaner.

Cleaning 3D printer beds

Glass

Due to its ability to disperse heat evenly and ease maintenance, glass is one of the most widely used and effective building materials. While some users attach a removable glass sheet (typically borosilicate glass) to a metal print bed, some printers have glass print beds.

Glass offers a flat printing surface, but good first-layer adhesion may not be possible due to its smoothness. Before printing, users frequently use glue or another adhesive to coat the glass surface. As a result, a buildup of residue occurs naturally and must be removed between prints.

Cleaning glass 3D printing platforms:

- If possible, remove the glass plate from the print bed to prevent the cleaning solution from getting inside the printer’s mechanical components.

- Use a dry scraper to remove any substantial chunks of glue or filament residue, applying firm, even pressure.

- Once a month or as needed, wipe down the glass with a cleaning cloth dipped in warm, soapy water to remove any grease or other residue (but only if the surface can be removed from the printer). You could also use a window cleaner.

- Put on safety gloves and wipe the surface between prints after soaking a cloth in IPA.

- Wherever possible, avoid leaving fingerprints on the glass.

Also, check the best 3D printing Glass Bed deals on Amazon.com

PEI

A chemically stable thermoplastic known as polyetherimide (PEI) is used as a printing surface because of its favorable material properties, including heat resistance. A build plate can be attached to inexpensive PEI sheets, which can withstand numerous print cycles.

The superior adhesion of a PEI sheet over a glass, especially with materials like ABS, is a benefit. Usually, no additional adhesive, such as glue, is applied to the surface, which lessens residue buildup. To keep a good adhesion, regular cleaning is necessary.

PEI 3D printing bed cleaning instructions:

- Remove the PEI surface from the print bed if possible to avoid the cleaning solution getting into the printer’s mechanical parts.

- Wipe the PEI bed surface with a dry cloth soaked in IPA to remove gunk and residue. Between prints, repeat this process. Alternatively, use warm water and dish soap.

- Once a month, apply acetone with a cloth to further smooth and clean the plastic surface.

- If the surface is scratched, smooth it out with fine-grit sandpaper. The PEI sheet should be replaced if the flaws are too severe to be fixed.

- Avoid getting fingerprints on the PEI.

Adhesive tape

Common build surfaces for FDM 3D printers without heated beds include blue painter’s tape, masking tape, and NASA-developed Kapton tape. (A heated bed might cause the tape’s adhesive side glue to melt.) A taped print bed may appear haphazard, but it functions well and is simple to replace.

Using adhesive tape has the obvious drawback of having tiny seams between each strip, which can leave a line on the base of a print. However, by using thicker tape, this issue can be somewhat reduced. Additionally, cleaning tape is more difficult than cleaning solid surfaces like glass because tape cannot be cleaned with solvents or other wet cleaning agents.

When blue painter’s tape becomes worn, it should be scraped clean and replaced.

Adhesive tape 3D printing bed cleaning instructions:

- Remove any residue and leftover filament with a dry scraper.

- Replace any tape that is damaged. Keep the surface level and even avoid problems with upcoming prints if possible.

- Avoid getting fingerprints on the tape.

- Replace the entire tape bed if it is visibly uneven, worn, or torn. Before putting on the new layer, clean the base with IPA or acetone to remove any glue stains.

BuildTak

BuildTak, a cheap, heat-resistant adhesive sheet that is simple to clean and replace, is one of the most widely used brand printing surfaces. Users speculate that even though its composition is unknown, it might be made of glass and PEI.

Clean BuildTak 3D printing platforms:

- Wipe the BuildTak surface with an IPA-soaked cloth to remove gunk and residue. Between prints, repeat this process.

- If the IPA doesn’t work, try using warm water.

- Avoid getting fingerprints on the BuildTak surface.

- Replace the BuildTak surface when worn and parts no longer adhere to the bed.

Conclusion

Many different print bed surfaces are available, and each is best for a particular print job. When printed onto a smooth surface like glass, ABS filament struggles, performing best on PEI sheet or BuildTak. PLA provides more options and functions well on a heated glass surface bed.

Regardless of the material you select for your 3D print bed, regular cleaning and maintenance are crucial to extending the surface’s life and ensuring strong first-layer adhesion, which will help prevent failed prints.

Always keep various cleaning supplies on hand, wipe down hard print surfaces in between prints, and perform a thorough deep clean every few weeks or months if you want to get the most use out of your FDM printer.

Which 3D printer bed cleaning solution is the best for you?

Let us know in the comments below or on our Facebook page to let us know your ideas, and we would appreciate seeing pictures of your works of art!