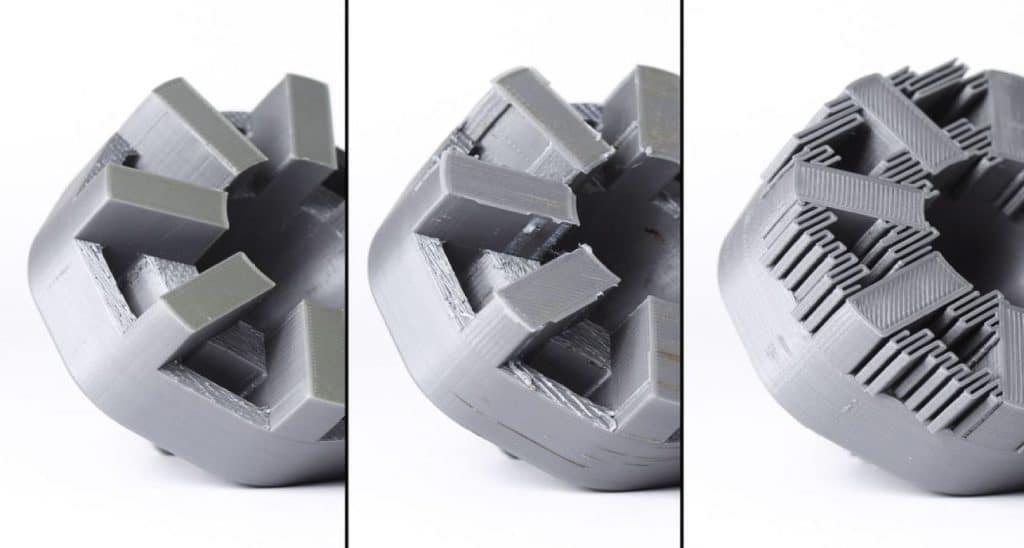

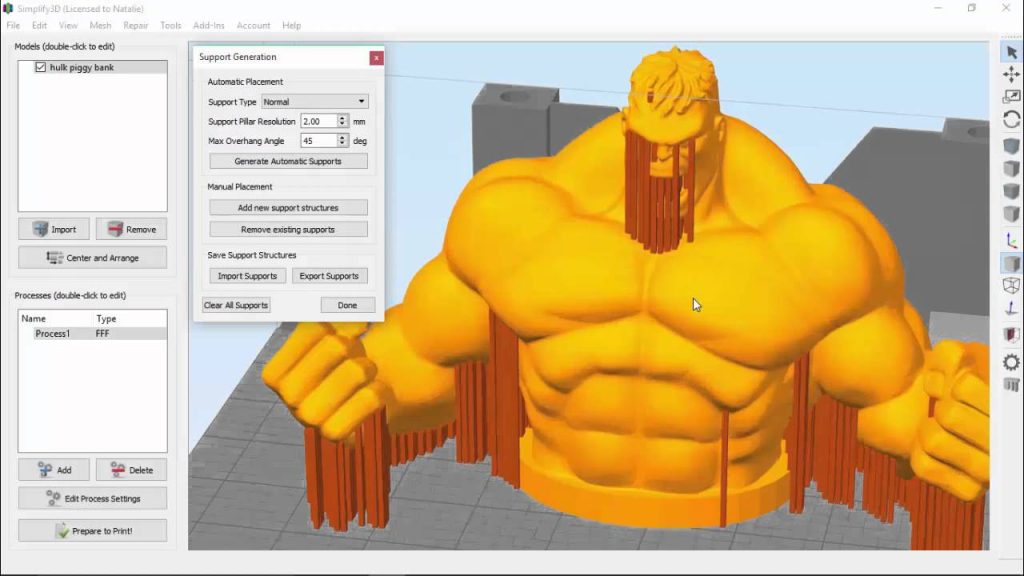

This tutorial will cover all the information you require about support structures. These frail, breakaway structures support your model’s cantilevered and steep overhanging portions. The Support Generation Tool makes adding, moving, and removing supports simple. The supports are built as a network of connected pieces so they can be removed from your model easily, despite appearing as individual pillars in the software. When are supports necessary? When models have pronounced overhangs or unsupported regions, supports are used. For instance, if you printed an arch, the center of the arch might need support material because nothing would support the top layer…

Author: Alex Killioglu

We can design all kinds of one-of-a-kind components using 3D printing, from cool figurines to intricate industrial models. Unfortunately, 3D printers can’t print through the air or defy gravity. Most entry-level 3D printers extrude material with many cost and safety benefits but also limitations. Designing a part with extreme overhangs, arches, or shallow angles can be difficult. Printing these geometries is made possible by supports. How, then, do you determine when a print requires supports? It varies based on the printer and the print’s layer height. Supports are typically needed when printing overhang angles greater than 45 degrees. Each layer…

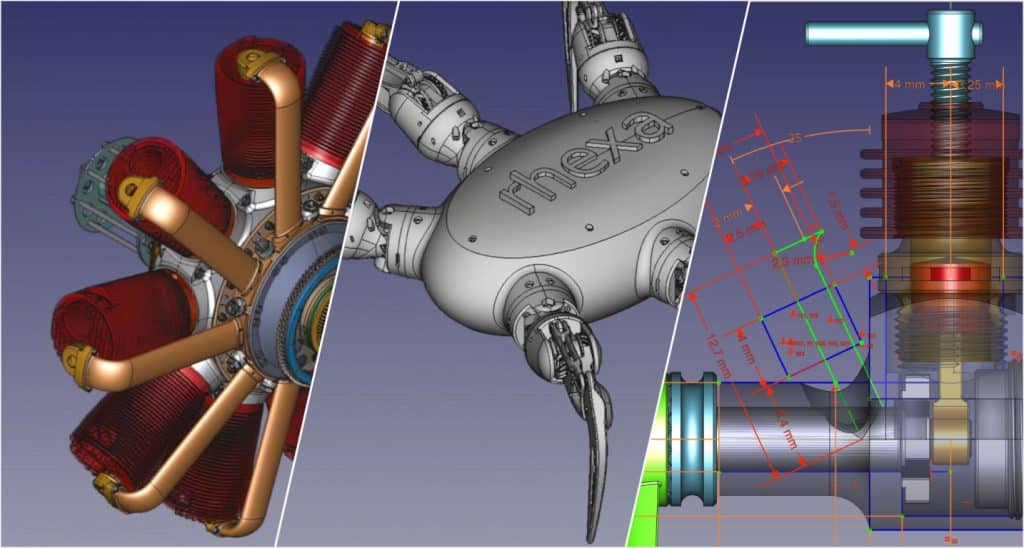

A 3D model must first go to a slicer in 3D printing before being sent to the printer. There are websites like Thingiverse where you can download various 3D models. But you’ll need modeling software if you want to build your models. One of these 3D modeling programs, FreeCAD, was created by Jürgen Riegel, Werner Mayer, and Yorik van Havre. It is open-source and free. Let’s explore FreeCAD’s advantages and disadvantages! One of the market’s most widely used modeling programs, it is currently available in version 0.20.1. The name suggests that FreeCAD is free and can be used to design…

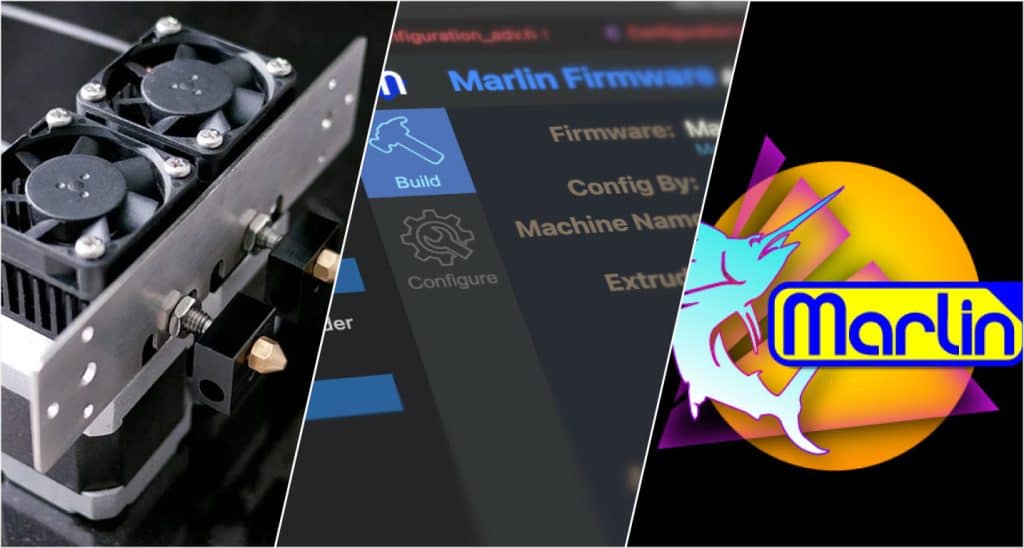

The most widely used 3D printer firmware is Marlin. Learn all the benefits of using it with your desktop 3D printer. For FDM 3D printers, CNC machines, laser cutters, pen plotters, and a few other devices, Marlin is open-source firmware. It is free for anyone to use and modify under the terms of the GPLv3 license. It is owned and maintained by the community. Marlin was first released as a standalone product in 2011, and it has its roots in the RepRap community. Since then, Marlin has steadily expanded within the 3D printing industry and is probably the most well-known…

If you want a print with incredible strength and exact details, 3D printing with resin might be your best bet. Despite its remarkable success, it can be challenging to fortify your resin prints to their highest level of durability. To learn how to make solid and less brittle resin 3D prints. We’ll walk you through each step and provide professional advice. Move along! Reduce your resin prints’ brittleness by: 1. Reduce the Isopropyl Alcohol Contact Time One disadvantage of resin printing is the lengthy post-processing required after printing. Before removing the print from the bed, the resin must first be…

The additive manufacturing (AM) industry frequently uses 3D scanning to create 3D models more quickly and easily than with modeling software. It gathers data later converted into a 3D model that can be printed using a 3D printer. Two key technologies used in 3D scanners—laser triangulation and structured light—allow for the acquisition of more or less precise details depending on the device selected. There are many inexpensive options available today to help many users bring their projects to life, as opposed to professional scanners, which are much more expensive: whether you are a maker, a teacher, or an industry leader,…

Cleaning your build surface is crucial for getting good prints whether you use a glass plate, PEI sheet, or something else! But are you cleaning 3D printer bed efficiently and without harming the bed? The first printing layer is frequently the most crucial in FDM 3D printing. Many unsuccessful prints result from poor first-layer adhesion, which can be brought on by inaccurate calibration, excessive print speeds, or an improperly prepared build surface. Keeping the build surface clean is one of the best ways to stop bed adhesion issues. The extruded thermoplastic has a better chance of adhering to a well-maintained…

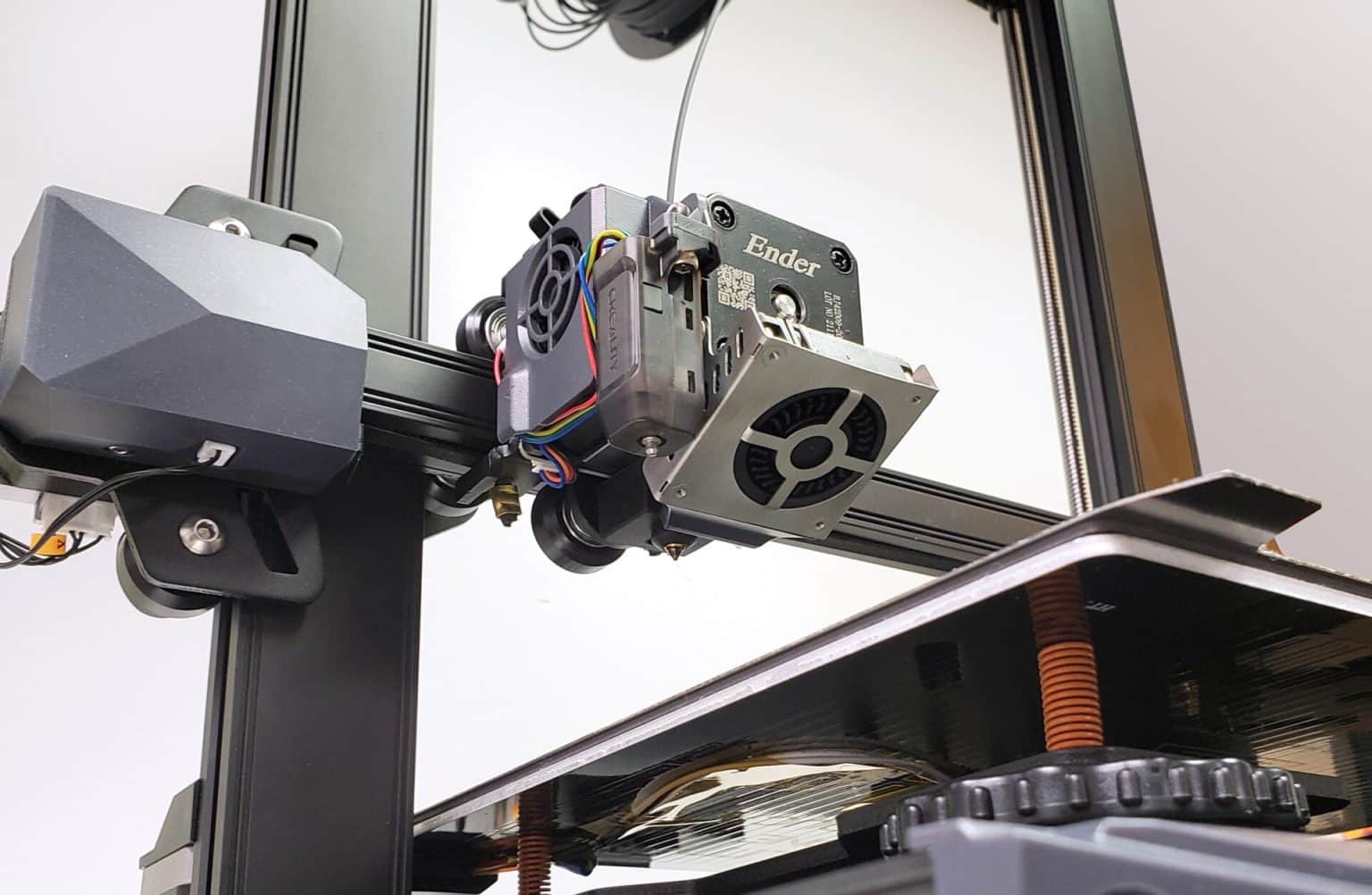

The Creality Ender 3 S1 might be among the hottest deals available during Black Friday. Continue reading to learn more. Creality Deals are currently flying everywhere because it is the selling season. Creality’s Ender 3 S1 is one of the prettiest cuts currently available, selling for an all-time low of $303.20 thanks to the company’s Black Friday Sale. The Ender 3 S1 produces excellent prints, it has a place in the Best 3D Printer listicle as the Top Pick for the sub-$500 price range, where it continues to snugly reside, outperforming many competitors, including more expensive alternatives. Although time has…

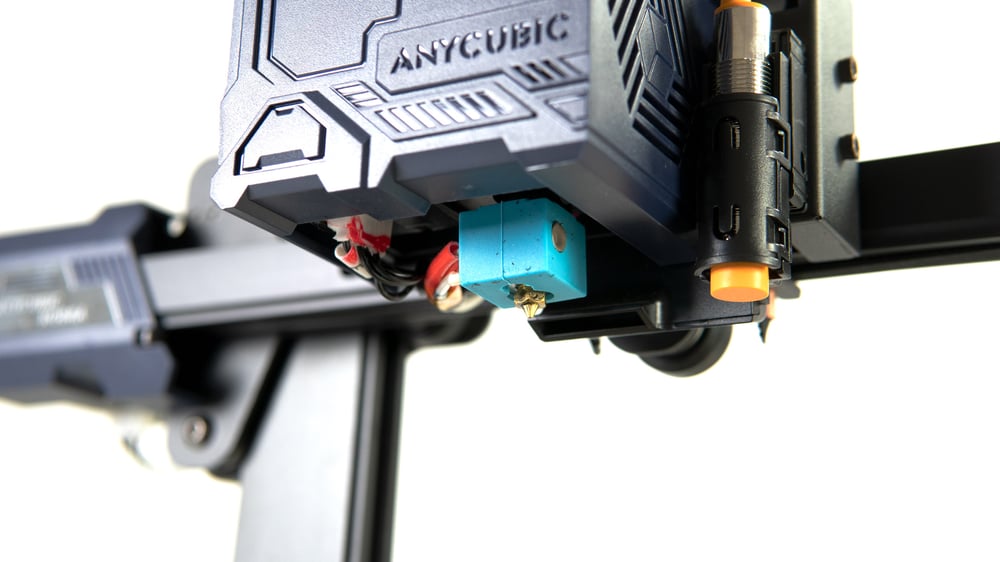

This week, the Anycubic Kobra, the best 3D printer under $300, is only $225. After reviews in April, the Anycubic Kobra, a 3D printer, was named the best 3D printer under $300. It is now limboing to an even lower price. Anycubic is selling the impressive system directly for just $225 during its Black Friday sale. Anycubic Kobra is a reliable machine with an impressive direct extruder and ABL that makes day-to-day printing tasks easy. We already praised the machine as having a “great bang-for-buck ratio” at its previous price of $299, so shaving another $74 from that price makes…

Usually, you’ll want to print with an SD card, but they can be fiddly, so a USB cable is a better option. However, you’ll need some software to send files to your 3D printer for printing. I’ll show you how to connect Ender 3 to pc and print in the sections below. Required Hardware How To Connect Ender 3 To Pc: Step By Step Guide Step 1: Get a USB Cable The Micro USB cable is the most common, and Creality adopted it with their 32-bit mainboards, which is fantastic. You will, however, require a mini USB cable if you…