Overhangs are a necessary evil in 3D printing. Learn how to conquer extreme 3D printing overhang problems with all of our tips and methods!

What is 3D Printing Overhang, exactly?

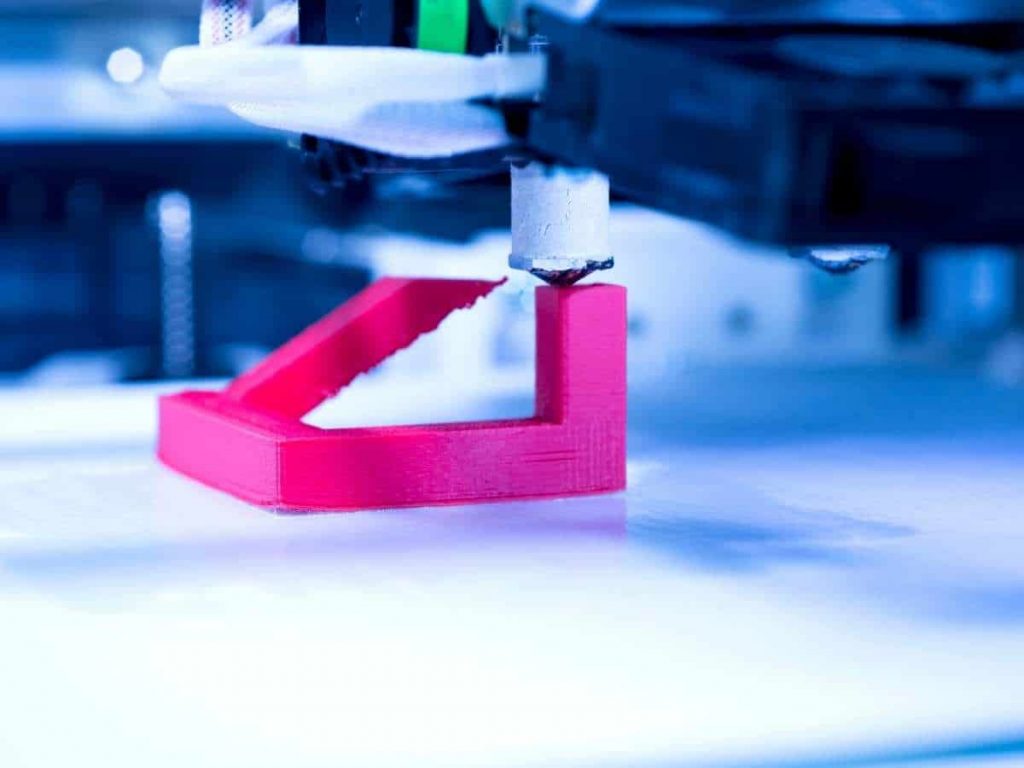

We’ve all been there, staring at a print with an unsightly, drooping overhang and scratching our heads. The underside of a slope, printed in midair without any physical support, is the bane of all FDM 3D printing designers.

3D printing overhangs are a result of 3D printing’s standard layer-by-layer method. Each successive layer must extend slightly beyond the layer before you reach the underside of a slope like the one seen above. This is when things might get messy: some of the plastic will float away, and gravity will begin to pull it back down. We can classify the overhang as printable or excessive depending on the angle of the printed slope.

The 45° rule is a valuable tool for determining overhangs. This guideline indicates that slopes less than or equal to 45 degrees can be printed without support; slopes greater than may require support. Supports aren’t ideal because they can ruin prints, add bother, lengthen print times, waste material, and even limit printable geometries (e.g., internal cavities).

The 45-degree rule is, of course, more of a recommendation. It can even lean on the conservative side for most current printers. Our ability to correctly and cleanly generate steep overhangs has improved as cooling solutions and slicing software has improved.

What happens if you print a steep enough overhang? The end outcome is usually one of two issues:

Drooping: When the plastic is dragged down by gravity before it solidifies, it droops. You’ll wind up with sagging, drooping plastic strands below their intended position.

Curling occurs when the plastic is not adequately cooled and begins to bend upwards. You’ll see that some print portions have curled above the nozzle height as the model prints. You’ll have a rough, uneven surface after the print is finished, which may resemble minor drooping.

We’ll look at how to avoid these concerns while printing your overhangs in this article. In addition, if necessary, we’ll show you how to avoid 3D printing overhangs. In conclusion, you’ll be well-equipped to confidently tackle challenging slopes.

Let’s get this party started!

Tune Your Machine as a Preparatory Step

First, you must improve your printer’s functioning and print settings before optimizing your overhang settings. This will provide you with a solid basis for building your 3D printing overhangs.

To begin, ensure that your 3D printer is calibrated correctly. Extruder calibration and entire printer calibration are covered in detail in our technical manuals.

Steps to alter basic material settings are also included in the printer calibration guide. We’ll modify these parameters to enhance your 3D printing overhangs, so make sure they’re in the right ballpark. Even if they’re not ideal, you should be able to get consistent prints with your current settings.

Once you’ve set up your printer and basic settings, we can get started.

Tip #1: Make Sure Your Filament Is Dry

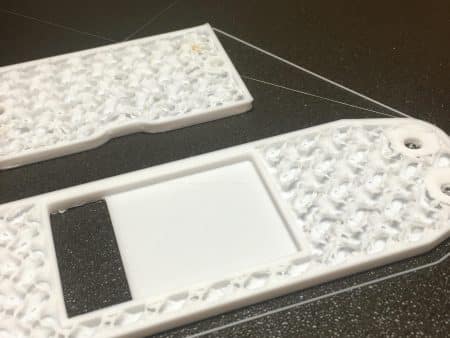

Because most FDM filaments are hygroscopic, they absorb moisture readily, wreaking havoc on the filaments. The wet filament is a well-known source of several printing flaws. Filaments are polymeric polymers made up of chains of molecules connected together. Moisture puts water molecules into these chains, destroying the plastic and producing many printing issues. This loss of integrity, particularly for overhangs, can increase drooping and surface roughness.

Fortunately, identifying and drying damp filament is a simple procedure. You can use our dedicated filament drying guide, which walks you through common symptoms, including “fuzzy” surfaces (seen above) and simple moisture removal methods.

Tip #2: Reduce the Nozzle Temperature

Insufficient cooling causes both drooping and curling (warping). You can improve your printer by reducing the nozzle temperature.

Your printer will have to work less cooling the filament if the temperature is reduced. As a result, the plastic will firm faster, reducing drooping and curling.

We recommend building a temperature tower, such as the one provided on our PLA print settings page, to determine the best temperature for your material. Keep the temperature as low as possible while maintaining adequate strength for the most precise results. The quality of the 3D printing overhang will almost certainly increase dramatically.

Tip #3: Slow down the printing process

Lowering the print speed, like lowering the nozzle temperature, gives the plastic more time to cool. In the meantime, the slower flow rate relieves some of the strain on your extruder, allowing you to drop the nozzle temperature even further.

Consider increasing the minimum layer time if only little 3D printing overhangs are causing problems (just slows down smaller layers). If that doesn’t work, try printing many models at once to allow each layer to cool more thoroughly.

Slower print speeds usually result in better print quality. However, you must be careful not to overdo it. Printing too slowly, especially on little layers, might allow the hot nozzle to linger too long, causing overheating problems to worsen. To find a happy medium, experiment with your settings.

Pro Tip: Increasing print speed is a good idea in some circumstances. This causes the cloth to stretch, which adds tension to the print and helps it hold its shape (much like while bridging). This is particularly true if you already have a reliable cooling system (discussed in the next section).

Tip #4: Boost Cooling

We haven’t even looked at your fan speed despite all the hype about cooling! There’s absolutely no such thing as “too much cooling” with PLA. Still, you’ll have to be more cautious with high-temperature materials like ABS or PC. For 3D printing overhangs, higher is better. Before the layers start to delaminate, you’ll want to establish a happy medium.

If even a 100% fan speed isn’t enough, you might want to consider replacing your fans and fan ducts. Upgrade to radial fans or go for higher-power fans that pump more air. These have a higher pressure output, which works well with excellent fan ducts for more targeted cooling. Many user-designed ducts can be found on the internet.

Consider increasing your print speed if your fans can provide powerful cooling over a large area. This prevents overheating by relocating the hot end and allowing the fans to cool the plastic.

Tip #5: Adjust the Layer Height

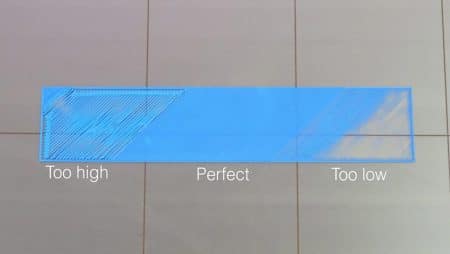

Because 3D printing overhangs suspend routes in the air, they are challenging to navigate. By lowering the layer height, you can reduce the effect.

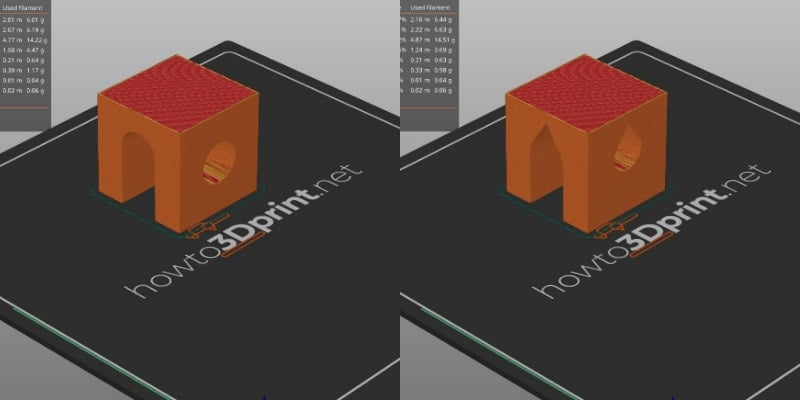

You’re printing stair-stepped layers when you print slopes (pictured above). At finer layer heights, more steps can be packed into span the same distance, resulting in each layer protruding less from the one below. As a result, there is less suspension per layer, which means less drooping.

Thicker layers, on the other hand, are stiffer. Consider the difference between a thin sheet of paper and thick card stock. It means that thicker layers resist drooping better in 3D printing, even if they protrude more from the one below. Even if each layer droops a little, the result is a steady slope. As you can see in the illustration above: The overhang is in good form, but each layer has drooped somewhat.

Another advantage of thicker layers is that they can help to prevent curling. While heavier layers increase the amount of cooling required, they can assist keep the print from lifting up by pressing down on it.

Finally, depending on the overhang symptoms and your ultimate aims, we recommend modifying your layer height to meet what works best for you.

Tip #6: Adjust the Shell’s Parameters

The walls that surround the infill of your print are referred to as the “shell.” There are a few adjustments you may make to fine-tune your 3D printing overhangs:

Extrusion width can be changed: a thicker extrusion width is more difficult to cool, but it increases overlap with the layer below. To find an excellent midway ground, adjust this value.

Optimize the printing order on the wall: You can usually select how your shell is produced with most slicers. Inside walls should be printed first, followed by exterior walls, to avoid starting layers in the middle of the process. Due to this, the overhanging paths will be able to “hold” onto the inside paths.

Increase the number of pathways in your shell: More paths in your shell means more overlap between layers. Additional interior routes will be to “hold” onto the outer paths.

Tip #7: Avoid Overhangs

If none of the above solutions appeal to you, remember that overhangs may always be avoided! This can be accomplished in a variety of ways:

Consider 3D printing overhangs while constructing your own model: When designing your own model, consider how your part will be orientated to eliminate overhangs as much as possible. To support overhangs, consider replacing fillets with chamfers or adding structures beneath them. To avoid drooping at the top, use a teardrop form for horizontal holes (pictured above). When you come across a sharp overhang, you can turn it into a straight bridge, making it easier to print.

Change the way things are done: Print orientations aren’t all created equal. Specific arrangements will result in drastically reduced overhangs, depending on your model. The image above is an excellent example: 3D printing overhangs can be entirely eliminated by reorienting the letters ‘T’ and ‘E,’ which require support in their original position.

Split the model up: At times, overhangs are unavoidable on a complex model. That’s when you should think about dividing it into multiple files. As illustrated above, this can make previously tricky prints simple. Simply glue the parts back together once they’ve been printed!

Use supports: If you really need them, don’t be afraid to ask for them! Dissolvable supports, in the example, can be used for more intricate structures that can be wiped away, leaving cleaner bottom surfaces.

That concludes the discussion. You now know how to overcome excessive overhangs and some alternatives if you choose to avoid them.

Check out our complete troubleshooting guide for more tips like these!