We can design all kinds of one-of-a-kind components using 3D printing, from cool figurines to intricate industrial models. Unfortunately, 3D printers can’t print through the air or defy gravity. Most entry-level 3D printers extrude material with many cost and safety benefits but also limitations. Designing a part with extreme overhangs, arches, or shallow angles can be difficult. Printing these geometries is made possible by supports.

How, then, do you determine when a print requires supports? It varies based on the printer and the print’s layer height. Supports are typically needed when printing overhang angles greater than 45 degrees. Each layer is already supported by the layer below, so no additional support is required as the sidewalls of the print approach vertical (0 degrees) or overhangs approach 90 degrees. Layers may now start to deform and warp independently of one another.

When appropriately configured, supports will effortlessly separate from a finished print, leaving little to no trace that they ever existed. Continue reading to learn how to perform an overhang test and how to use Simplify3D to generate support automatically.

Test the overhang first

Finding out what kinds of angles your printer can successfully produce without the use of supports can be done by running an overhang test. A series of increasing angles are used in this overhang test print to demonstrate the point at which the printer starts to experience issues. The results of this test will be used to determine the Max Overhang Angle in Simplify3D.

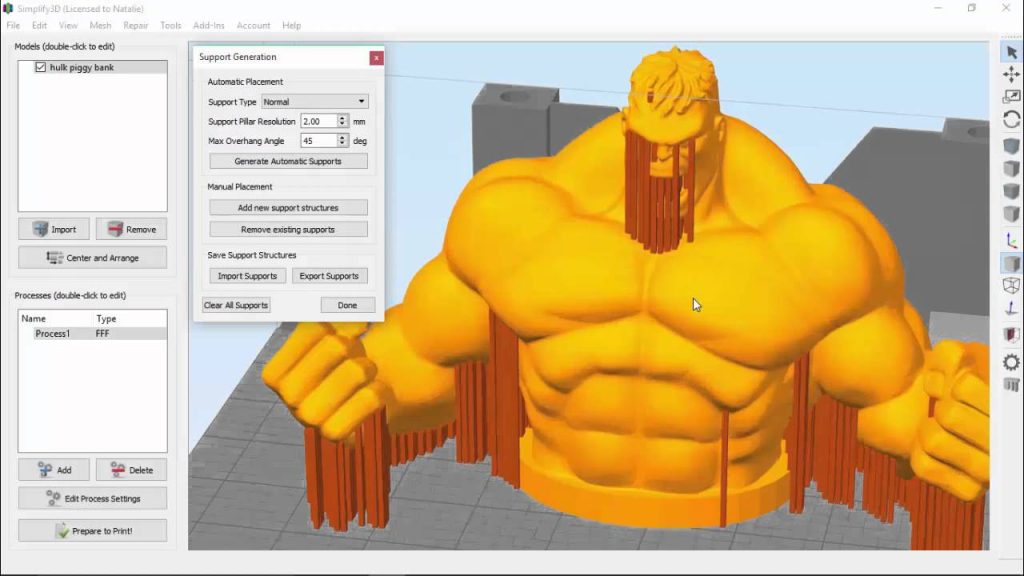

How to Create Supports in Simplify3D Automatically

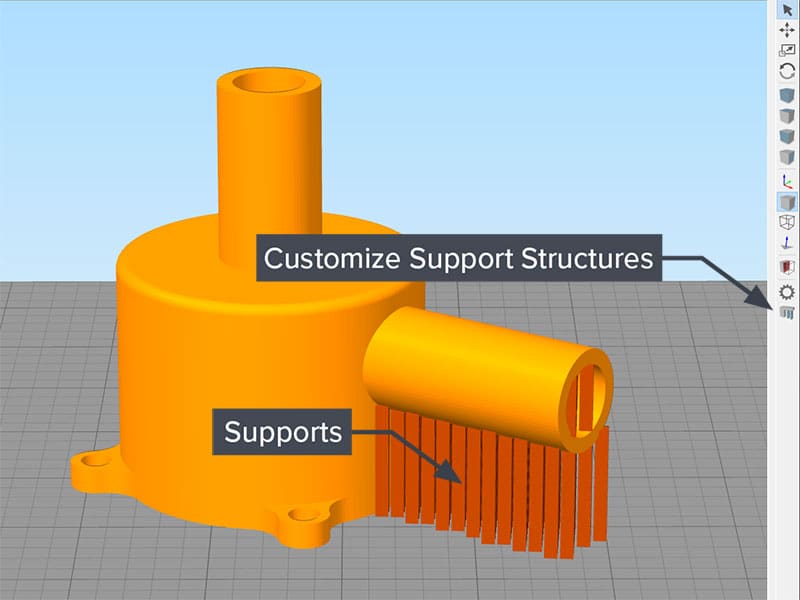

Supports can be added, removed, and customized with ease using Simplify3D. Although the software offers a variety of configuration and creation options, the Customize Support Structures icon is the best place to start. Click on ![]() from the sidebar of the program.

from the sidebar of the program.

Using the Customize Support Structures tool, you can:

- Select the Support Type – “Normal” is the default selection for most prints that demand support. For a more in-depth discussion of Support Type options, watch the video.

- Set the Support Pillar Resolution – This determines the width of the support pillars. The default is 4 mm. A lower setting of 1 or 2 mm will probably be necessary for prints with greater detail. Be cautious because thinner supports tend to be more brittle and unstable while printing.

- Set the Max Overhang Angle – Recall the outcome of the above overhang test. It can be used to configure the maximum overhang angle. The Max Overhang Angle should be five degrees less than your test value. We advise setting the Max Overhang Angle to 45 degrees, for instance, if the printer starts having issues at 50 degrees.

- Click on Generate Automatic Supports – The required support structures will be created after the software has analyzed the part. Dark orange will show up for the supports.

Simplify3D also gives you total control to customize the supports after you add the automatic supports using the settings above. Although Simplify3D does a great job of placing supports automatically, there may be times when you want to add more or less support in particular areas. In areas that you believe are particularly prone to failure, you can add supports; in areas that already have excessive support, you can remove supports. Learn more about changing supports by reading this article.

Although supports aren’t necessary for every part, they significantly affect the success of some prints. Knowing how to perform an overhang test and generate support structures in Simplify3D will enable you to produce prints of the highest caliber constrained by your creativity and never by gravity.

After discovering a quick method for automatically placing supports, develop your knowledge of 3D printing by reading our in-depth articles. We cover a wide range of topics in our beginner, intermediate, and advanced sections, including bed-leveling fundamentals and Simplify3D printing with multiple extruders.

Have you used the Simplify3D support feature? If the answer is yes…

Let us know in the comments below or on our Facebook page to let us know your ideas, and we would appreciate seeing pictures of your works of art!