In the world of 3D printing, Creality’s hot end is a workhorse. Its simple design makes it suitable for use in one of the most popular 3D printers, the Ender 3, and its successors, the Ender 3 Pro and the Ender 3 V2. The Ender 3 nozzle size is 0.4mm and Ender 3 printers come standard with a 0.4mm brass nozzle size that fits the heat block via an M6 thread.

The nozzle configuration is an MK8 hot end in the RepRap 3D printer community. These printers employ the MK8 because of its simplicity, efficacy, and open-source nature, with a wide following among hobbyists.

Brass is in charge.

The brass 0.4mm nozzle reigns supreme in the world of FDM printing, and the Ender 3 is no exception. Brass is a good default material because it is inexpensive, easily formed, conducts heat well, and does not tarnish or oxidize quickly.

Naturally, brass has drawbacks, such as being soft and not holding up well against the abrasive nature of more exotic filament types. However, considering the Ender 3s’ price range and most hobbyists’ print in primary filaments such as PLA, ABS, and PETG, the nozzle’s accessibility and low price have made it the ideal complement.

Standard sizing

Given Ender 3 Nozzle Size, the 0.4mm nozzle diameter is a good compromise. This diameter is small enough to quickly produce workable layer heights ranging from 0.12 mm to 0.24 mm. Furthermore, it is large enough that most particulates will pass through easily, resulting in fewer clogs.

The question is, do the Ender 3 printers come in any other sizes? Continue reading to learn about your options for more extensive and smaller nozzle diameters. In addition, we’ll examine some of the more unusual nozzles available for the Ender 3s, which have various material qualities or serve particular functions.

Is it true that Ender 3 Nozzle Size changes the speed of 3D prints?

While the 0.4mm nozzle diameter of the Ender 3s is a suitable middle ground, there are additional options. But why would you want to adjust the size of your nozzle? What happens to prints when you swap out the regular Ender 3 nozzle for a bigger diameter?

Why go bigger? (0.5, 0.6, 0.8, and 1.0 mm)

BENEFITS

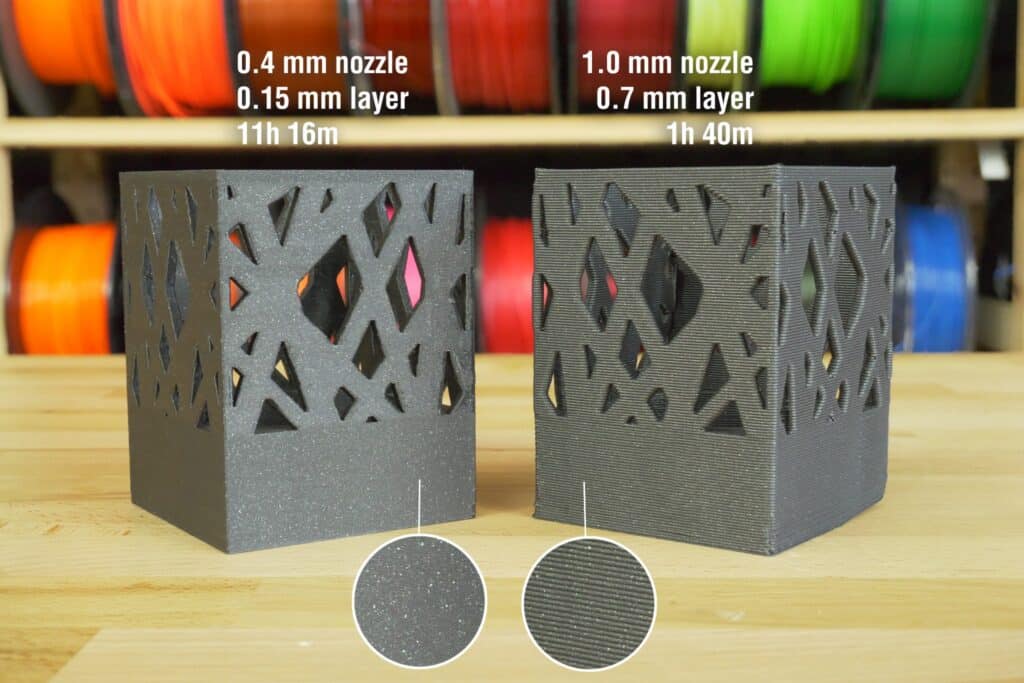

Faster print speeds: 3D printers draw objects layer by layer, so a larger nozzle allows for greater layer height. Because it takes fewer passes to produce the item, the greater size allows for a faster print time.

Because it takes fewer passes to produce the item, the greater height allows for a faster print time.

More powerful parts: The production of layers in the printing process is one factor in weaker items in 3D printing than injection molding. There are fewer layers when a bigger nozzle is used, but each layer is more significant and more consistent. Another result is that the larger layer strands have more surface area to bind to one another.

DRAWBACK

Hot end requirements: A larger diameter nozzle allows more plastic to be pushed out. The disadvantage is the heat required to keep the plastic melted to the heat break on the nozzle. If the hot end is incapable of heating the bigger mass of plastic, the only option is to print at a slower speed.

Visible layers: One of the main objections to large-nozzle 3D printing is, “Yeah, but I can see layers all over it.” A larger nozzle will exaggerate the layer lines.

FINAL SAYING

If you need to print something large and robust, layers aren’t an issue, go ahead and upgrade the nozzle to 0.6mm or 0.8mm. Just be careful with a 1.0mm nozzle. The basic Ender 3 hot end struggles to pump that much plastic.

Is it true that a smaller Ender 3 nozzle size equates to higher quality?

How can you reduce layer lines? A smaller nozzle for your Ender 3 could be the answer.

Why would you want to go smaller? (0.2, 0.25, and 0.3 mm)

BENEFITS

Subtle layers: When specifying the layer height of a printer, you usually operate at roughly 50% of the nozzle diameter. A 0.2mm nozzle can easily manage 0.08mm layer heights if you want to make anything tiny and detailed.

Nozzle diameter influences not only layer height but also X and Y resolution. Therefore, more minor surface details can be captured using a finer nozzle that would otherwise be smoothed off or deleted by slicing software using a bigger nozzle.

DRAWBACK

Clogged nozzles: A 0.2mm nozzle is more likely to jam with the tiniest impurity or dust than a bigger nozzle because of its narrower opening. This is something that a good filament wipe sponge with mineral spirits can help with.

Slow print speeds: A low layer height can result in lengthy print times. Making anything with a 0.08mm layer height can take at least three times as long as making something with a 0.24mm layer height. That doesn’t even take into account infill or other non-linear factors.

FINAL SAYING

Consider utilizing a smaller nozzle if you want to make scaled miniatures with great accuracy, time is not an issue, and you are willing to suffer more maintenance. The attention to detail will astound you and your friends, who cannot believe it did not come from a resin 3D printer.

Materials from beyond

When we talked about nozzles larger than 0.8 mm, we mentioned that the basic Ender 3 hot end isn’t enough to keep up with heating the filament. Fortunately, businesses like E3D and its volcanic product line allow you to add larger nozzles to Ender 3 printers without sacrificing print speed. These methods increase the heat block’s metal mass and position the heater cartridge to create a wider melt zone in the hot end.

The material used to construct your Ender 3 nozzle also significantly influences. For example, when printing abrasive filament materials like carbon fiber or metal-filled PLA, the extrusion nozzle may need to be more robust than ordinary brass.

If you want to use an abrasive filament, here are some nozzles you can attach to your Ender 3 in the order of least wear-resistant to most wear-resistant:

Brass has high wear resistance and efficient heat transmission.

Stainless steel has higher wear resistance and is food-safe.

Carbon steel has high wear resistance.

Tool steel A2: High wear resistance

Copper with ruby sapphire: Excellent wear resistance and heat transfer

“PolyPhobic” Nozzle X: High wear resistance, requires E3D V6 hot end

With so many nozzles available, there is bound to be one that meets your requirements and application. We hope you enjoyed our look at alternative nozzle sizes for the Ender 3, Pro, and V2 and how they affect your prints. Happy printing, as always!

Get Your Ender 3 Nozzles