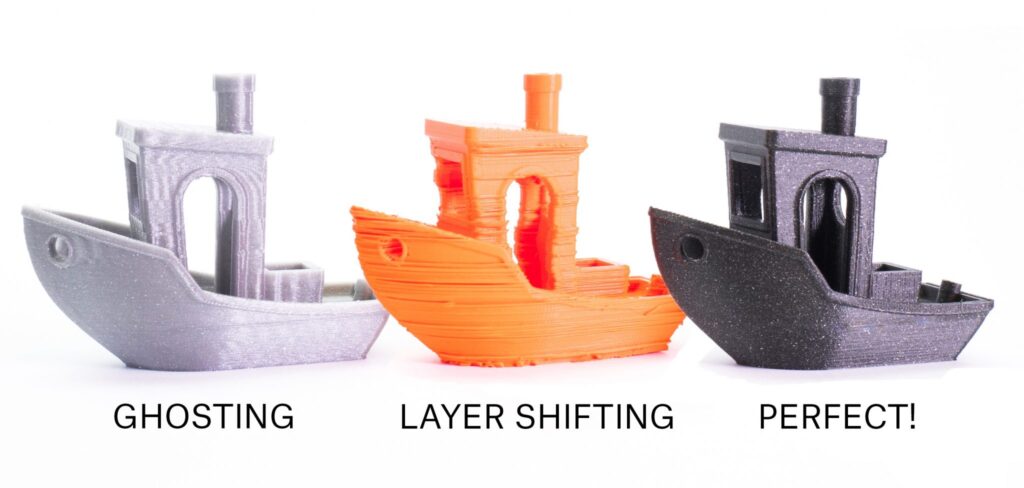

While there are numerous potential issues, 3D printing layer shifting is visible because it affects dimensional accuracy and visual appearance. This is because layer shifting occurs when layers are continuously and unintentionally moved in the same direction as the part is printed, with subsequent layers offset from previous ones.

Typically, each layer gradually moves towards one direction (sometimes two, but usually only one), resulting in an incorrectly slanted print that looks bad and does not function as expected. Layer shifting can also appear as a single large displacement at a specific layer.

Layer shifting irreversibly destroys prints, as there is no way to repair an affected model. However, by addressing the underlying causes, you can avoid this issue in future prints. In the video series, we’ll go over six simple and practical tips for preventing layer shifting. Each day we will share one method.

HOW TO AVOID 3D PRINTING LAYER SHIFTING

Tip #0: Proper Printer Calibration

Our first tip is rated “0” because it applies to almost all printing issues. When faced with a print-quality problem, such as layer shifting, the first step is to ensure that your printer is calibrated correctly. Tune precisely and check that all aspects of your 3D printer prevent 3D printing layer shifting. For a detailed calibration, click here.

Tuning your slicer profile (e.g., nozzle temperature and print speed), adjusting your E-steps, and tightening all relevant screws and bolts are all examples of proper printer calibration. You should also level your print bed, change or clean your nozzle, PID tune your hot end, and do whatever else is necessary to get your printer to print some test prints.

If you’ve calibrated and tuned your printer correctly and layer shifting persists, you should proceed to our first real tip.

HOW TO AVOID 3D PRINTING LAYER SHIFTING

Tip #1: Reduce Bumps and Vibrations

Our first real tip is to reduce the amount of bumps and vibrations that your printer absorbs or produces while printing an object. These can jolt the printhead and print bed along their paths, potentially causing layer shifting.

Bumps and vibrations can come from a variety of sources. To begin, ensure that your printer is not absorbing vibrations from the surface it is resting on. This entails positioning your 3D printer on a stable surface and possibly adding rubber vibration dampers to the bottom of your machine (3D printed or purchased).

Second, make sure your machine’s motors are running smoothly and aren’t jolting when changing directions. Third, ensure that no contaminants or debris are in the printhead’s or print bed’s path. (Occasionally, scraps of plastic can get into the printer’s frame, potentially affecting motion.)

Other vibrations or bumps may occur as a result of factors unique to your setup. Basically, you want to find the source of the extra movement in your printer and eliminate or reduce it as much as possible.

HOW TO AVOID 3D PRINTING LAYER SHIFTING

Tip #2: Tighten the Belts and Pulleys

Our second tip addresses the most common cause of layer shifting: belts that are too loose. Most FDM 3D printers use belts and pulleys to move the printhead. And print bed along their respective axes, but layer shifting can occur if the belts become loose. The slacker the belts have, the more space the printhead and print bed have to move freely.

So you want to tighten the belts on your machine by extending the pulley on one side of the belt loop to remove any slack. Some machines have belt pulleys that are easily adjustable and have knobs that you can twist to tighten the belt. To learn more about this process, read our article on tightening the belts on your machine.

HOW TO AVOID 3D PRINTING LAYER SHIFTING

Tip #3: Reduce the Print Speed

Third, try lowering your print speed to see if this is the problem. Print speed can cause a 3D printing layer shifting because it is set higher than your stepper motors can handle. As a result, the motors may move less than they should.

Still, you want the fastest possible print speed without sacrificing print quality. As a result, we recommend reducing your print speed by 20 to 60% while attempting to resolve layer shifting.

You should also ensure that your stepper motors perform as expected and keep up with the motion demand (they often make a clicking noise when failing). If you discover that print speed isn’t the cause of your layer shifting, you can always increase it back to the original setting.

HOW TO AVOID 3D PRINTING LAYER SHIFTING

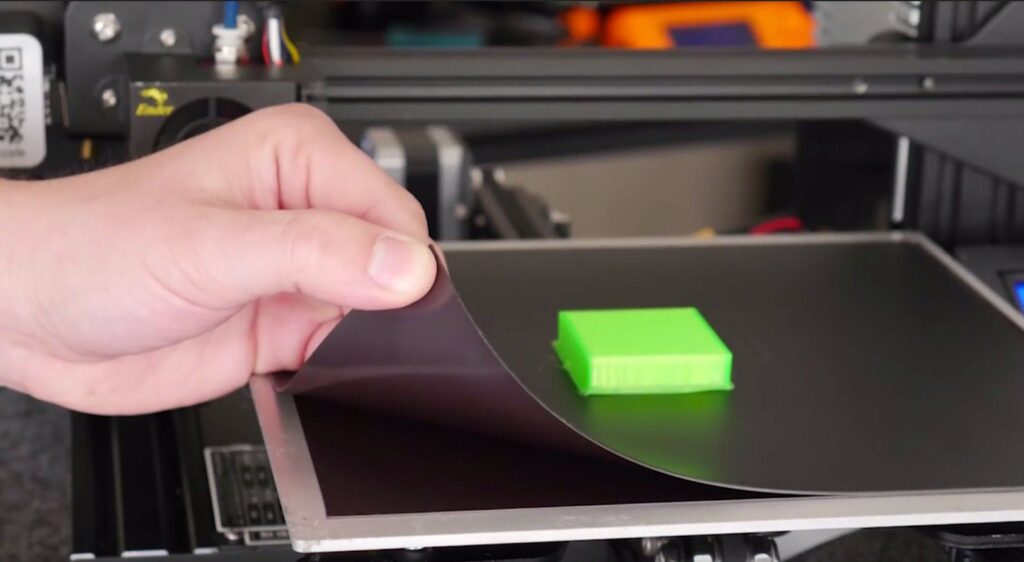

Tip #4: Secure the Printing Surface

Sometimes the cause of 3D printing layer shifting is more obvious than you think, and just one more binder clip can make all the difference. So our fourth piece of advice is to secure the build plate or printing surface all the way down to the print bed underframe, which is the frame component moved by the bed stepper motor. The build plate may shift if it is too loose while the print bed underframe moves back and forth.

You can use binder clips or 3D printer clips to secure the build plate to the print bed underframe. It’s common to have at least four of these clips (one on each corner) holding your build plate to the underframe, but you may want to use more.

HOW TO AVOID 3D PRINTING LAYER SHIFTING

Tip #5: Cool the Electronics

Our fifth tip is to keep the electronic components on your 3D printer cool. Because they can malfunction if they get too hot, potentially resulting in layer shifting in parts. Of course, we’re talking about your 3D printer’s stepper motor drivers, which are the components built into the mainboard that control the motion of the stepper motors.

You can solve this problem by increasing the airflow to your printer’s mainboard. You can either open up the mainboard casing of your printer to allow more air to reach and cool the drivers, or you can install a fan directly over the mainboard.

HOW TO AVOID 3D PRINTING LAYER SHIFTING

Tip #6: Avoid Collisions

Our final tip is to avoid printhead or nozzle collisions with the part being printed. If the nozzle collides with the printed piece, the piece may move, resulting in layer shifting later in print.

Collisions are more likely to occur when the shape of a print facilitates them. For example, small print features that come loose or a warped first layer can easily get in the way of the nozzle. To avoid this, ensure that your bed is level and that your first layer adheres well to prevent any features from accidentally hitting the nozzle.

Suppose you determine that collisions are the cause of your printer’s layer shifting. Try lowering your travel speed in addition to doing whatever is necessary to keep parts of your print from getting in the nozzle’s path. Of course, this will not prevent the nozzle from colliding with anything. But it will reduce the impact of objects getting in the way of the nozzle.

Another way to avoid collisions and 3D printing layer shifting is to enable Z hop in your slicer profile. When your printhead makes a travel move, this instructs it to move up on the Z-axis, preventing the nozzle from colliding with the print.