Strings, blobs, and jams are a hassle! Check out these three simple fixes to your 3D printer over extrusion issues that will last a lifetime!

What is 3D Printer Over Extrusion?

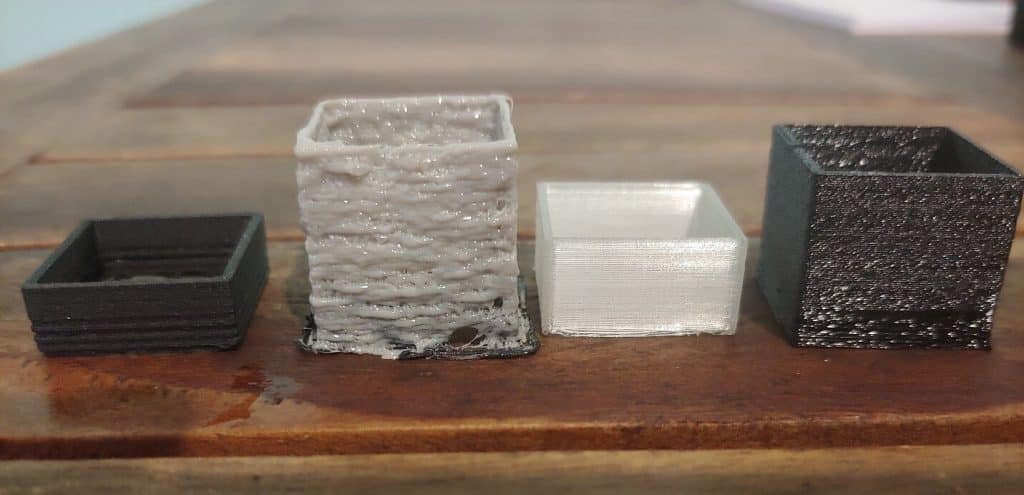

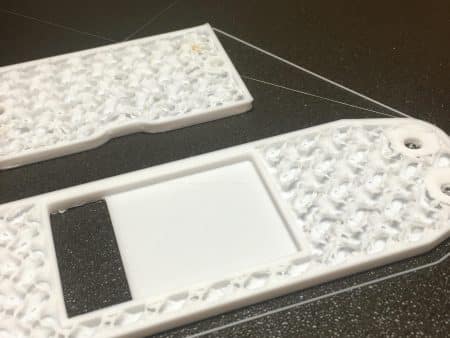

3D printer over extrusion occurs when your 3D printer extrudes too much material, as the name implies. As you may think, this can degrade the quality of your prints.

An over extruding printer can cause dimensional inaccuracies, layer drooping, stringing, leaking, blobs, and even jams. If any of these symptoms appear in your prints, you’re most likely suffering from 3D printer over extrusion.

Obviously, if at all feasible, you should avoid over 3D printer over extrusion. Let’s look at three slicer settings that can help you avoid over extrusion.

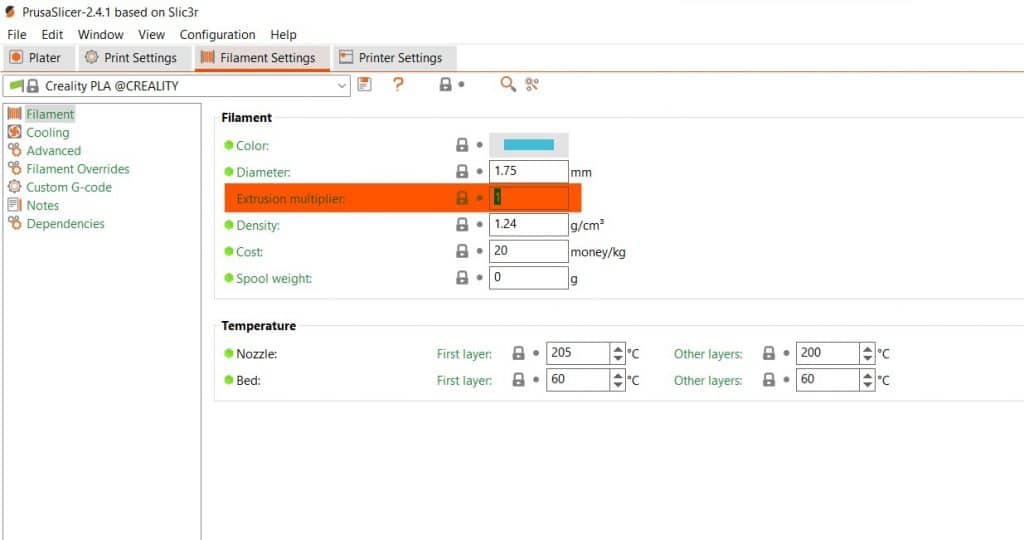

Tip #1 for 3D Printer Over Extrusion: Reduce the extrusion multiplier

The pace at which your printer extrudes plastic is determined by the extrusion multiplier (or flow) parameter in 3D slicers. The default value for this parameter is 1 in most slicers (or 100 percent ).

Your extrusion multiplier is likely incorrect if your printer has excessively thick layers or nozzle jams. Reduce this value by 2.5 percent if your printer extrudes too much material.

If you reduce this setting too much and the problem persists, or a new problem arises, you should try a different setting.

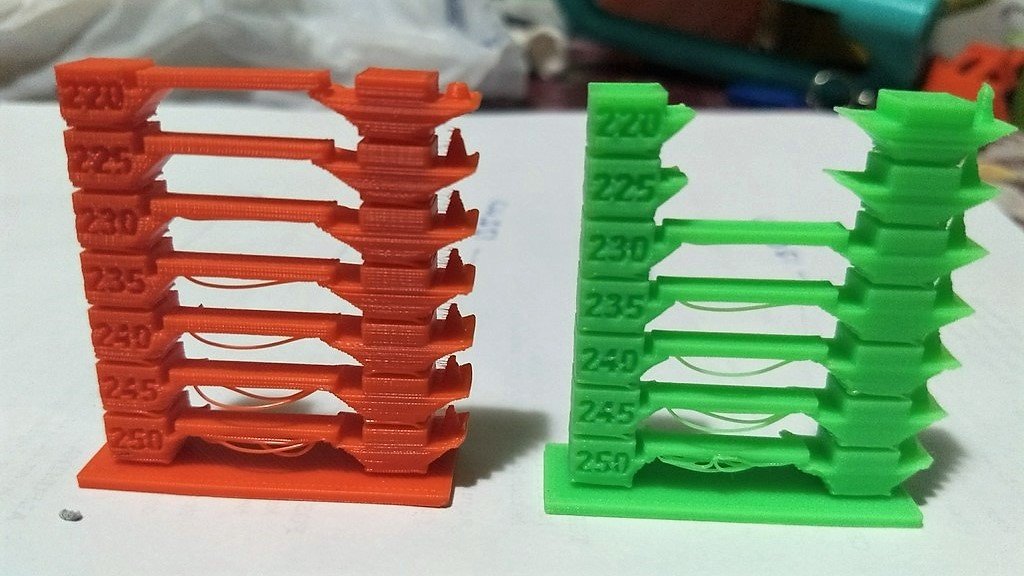

Tip #2 for 3D Printer Over Extrusion: Reduce the print temperature

If the first tip doesn’t work for 3D printer over extrusion , try lowering the print temperature. Overheated filament, which runs uncontrollably from your printer’s nozzle, is the apparent result of a high print temperature.

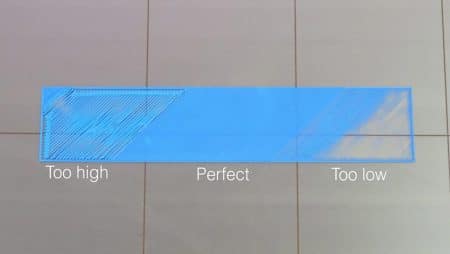

Reduce your printer’s print temperature (for the specific filament in use) by 5 degrees until you reach the ideal temperature for your machine and material. If over-extrusion or another issue persists in your prints, move on to the following setting.

You may fine-tune this setting by repeating a single test print or printing a temperature tower that allows you to test multiple temperatures for your machine and material.

Check different Temperature Tower models.

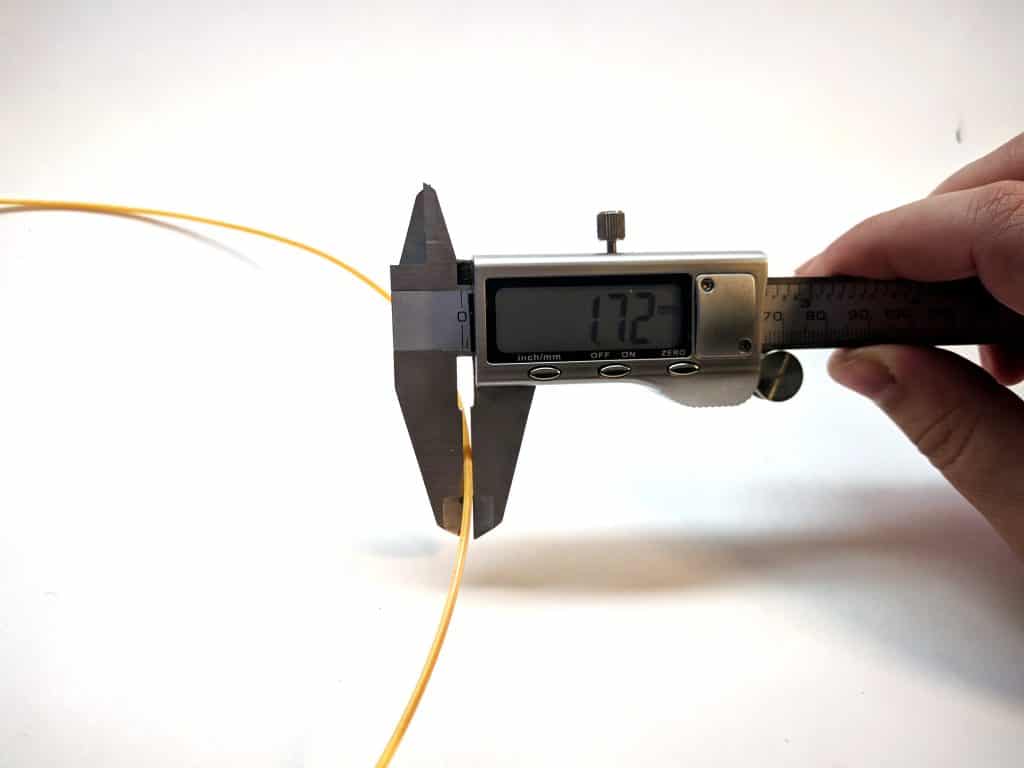

Tip #3 for 3D Printer Over Extrusion: Make sure your filament diameter is correct

An improper filament diameter input is a dreadful but all-too-common cause of over-extrusion. 1.75 mm, 2.85 mm, and 3 mm are the most common filament sizes. The extruder will extrude your filament faster if your slicer assumes a thinner filament diameter than you actually use. 3D printer over extrusion occurs as a result of this.

Hopefully, correcting one or more of these settings will eliminate the consequences of over-extrusion in your prints.

Happy 3D Printing!