Meat has always been a vital component of meals in all cultures regarding our diets. The US consumes meat at the second-highest rate in the world.

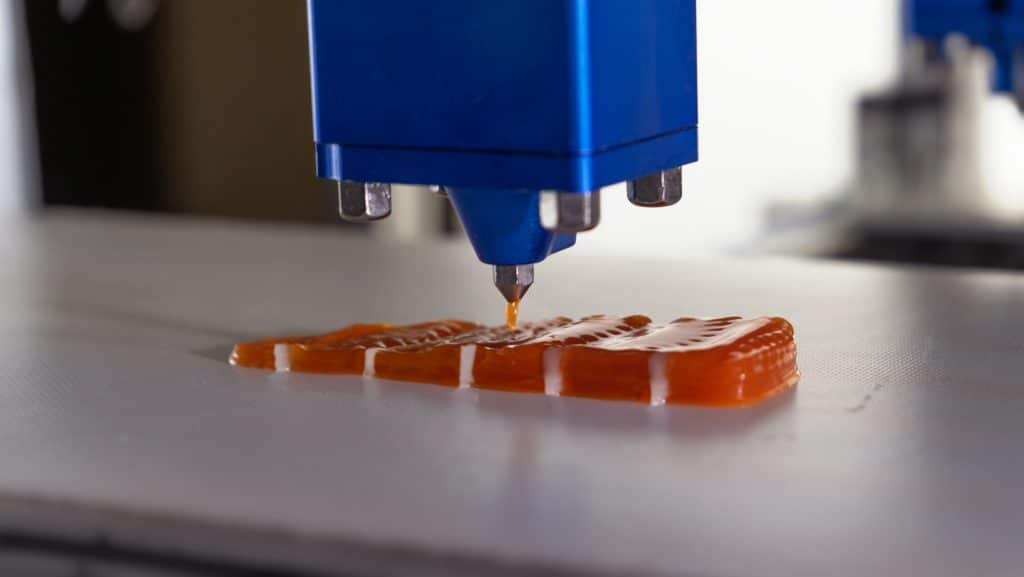

The consumption of red meat and poultry per capita is anticipated to decline in 2022, though this trend has already begun. Additionally, the growing demand for meat and fish substitutes shows that society’s consumption patterns are changing. Revo Foods, an Austrian business that uses 3D printing to create premium plant-based seafood, has been covered by us in the past.

It was the first to introduce salmon and tuna that were printed in 3D. The fact that these goods are currently stocked in more than 3,000 shops highlights the demand for meat alternatives. Because of this,

Mycorena, a food technology company, has pursued sustainability since its founding in 2017.

They produce vegan proteins for food using their technology, which is based on mushroom biotechnology, and they do so in a sustainable and resource-effective manner! To advance research into the use of Mycoprotein in 3D food printing and offer fresh seafood substitutes, the Swedish company is seeking a partnership with Revo Foods.

Meat and fish consumption is sustainable and vegan thanks to 3D printing.

Both sliced meats and seafood are anticipated to profit from the innovation in the Mycorena and Revo Foods research projects. This is made possible by Mycoprotein’s characteristics resembling meat and its potential for various shapes. The outcome? Now, 3D printing can be used to create an entirely new product category that is still related to meat.

Long-term, the goal is to remove the barrier between animal-based and plant-based or vegan products, increasing social acceptance of meat and fish substitutes.

Overall, the products should have a light color, a neutral flavor, and a soft, fibrous texture provided by the printable Mycoprotein. And because of that, it’s an excellent substitute for foods like fish and meat. “Our interest in 3D printing food has always been piqued. We realized that developing a printable mycelium material could create unique, original products.

Compared to current meat analogs, the possibilities for texture and form are on a whole new level with this technology and are only limited by the imagination as opposed to processing techniques, “revealed Paulo

According to Robin Simsa, CEO of Revo Foods, “Revo Foods is also pleased and optimistic about the partnership with Mycorena and the production of vegan products thanks to 3D printing.”

“The fibrous behavior of Mycoprotein, a very intriguing ingredient for vegan seafood substitutes, previously prevented us from using it in our unique 3D food printing process.

3D Printed Vegan Seafood

There is an excellent opportunity to advance the printable Mycoprotein through this new partnership with Mycorena, elevating meat and seafood substitutes to the next level of quality and enabling widespread consumer adoption.

The 3D printed food also has several additional advantages. Producing only what is required saves storage space, improves mouthfeel due to natural sensory characteristics, and is thought to have delicious ingredients.

“We are overjoyed to finally announce our partnership with Revo Foods. We are confident that the products we develop here will be truly distinctive, enabling customers to easily indulge in delectable seafood healthily and sustainably, said “The R&D Manager at Mycorena Kristina Karlsson. Please click here to learn more about 3D printed vegan food if interested.,

Do you want to taste 3D printed vegan seafood?

Let us know in the comments below or on our Facebook page to let us know your ideas, and we would appreciate seeing pictures of your works of art!

Photo Credits: Mycorena