The Anycubic Kobra is one of my favorites. It's easy to put together and use, and it just works. This is an excellent first printer for someone new to the activity, as well as a nice gift for a teen who wants to improve their STEM and Maker skills.

This printer should appeal to experienced makers as well, as it is a low-maintenance equipment. Because it's built totally in-house by Anycubic, I'm not sure how straightforward it would be to upgrade. However, because the Anycubic Vyper was such a hit, I'm confident that third-party manufacturers will provide an all-metal (or bi-metal) hotend for it shortly.

-

Design9

-

Specs10

-

Noise Levels7

-

Ease of use9

-

Print Quality9

-

Price9

Anycubic Kobra Review Features

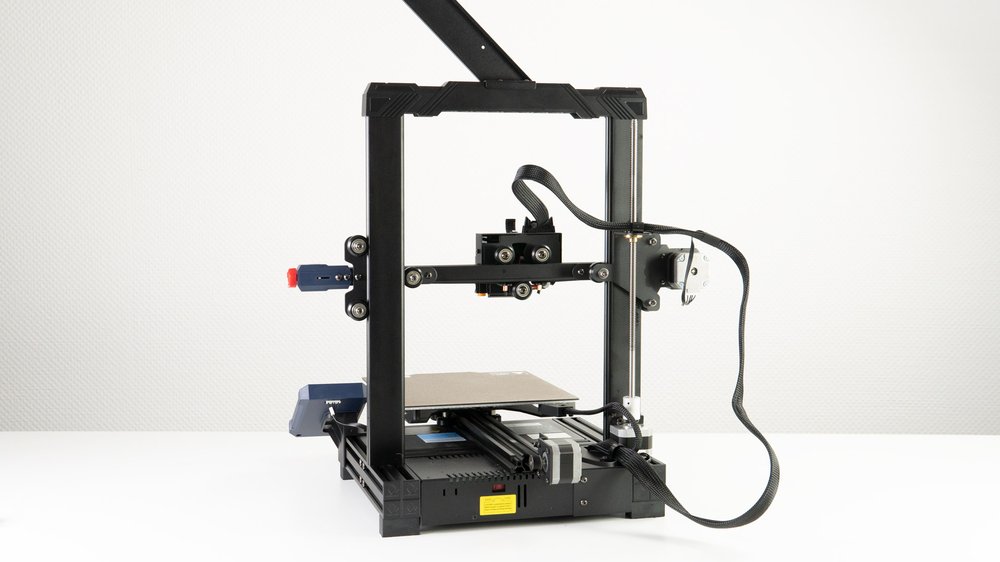

Anycubic has released the Anycubic Kobra, a new FDM 3D printer that offers superior capabilities at a low price.

Anycubic Kobra Review BUILD VOLUME, BED ADHESION

The Kobra’s construction volume of 222 x 222 x 252 mm is a couple of millimeters greater than typical in all directions. The grainy PEI-coated flexible magnetic bed in this build volume provides excellent traction on PLA and TPU prints. PETG adheres effectively, however it may benefit from an interface layer of adhesive to minimize oversticking.

Anycubic Kobra Review DIRECT EXTRUDER

There’s no Bowden in this place. The Kobra makes use of a geared direct extruder that looks a little like the E3D Titan Aero. However, there are notable variations, such as the drive gear that bites into the filament being a conventional toothed drive gear rather than a more specialized to the purpose “hobbed” gear.

The extruder’s reduction gearing means it’s powerful, but not particularly subtle. A basic PTFE-lined hot end that accepts E3D V6-style nozzles melts the filament.

Anycubic Kobra Review AUTO-BED LEVELING

The Kobra lacks manual bed leveling, so Anycubic’s LeviQ – an inductive probe-based mesh-bed leveling technique – is used for all first-layer fine-tuning. We don’t see anything unusual about it. The procedure will be familiar to anyone who has done mesh-bed leveling on other printers. When you run the program, it will map out 16 spots across the bed and their deviations. This is then accounted for in the early phases of a print to ensure a smooth and consistent initial layer.

Anycubic Kobra Review SENSORLESS HOMING

Stallguard is activated out of the box on the Kobra, which is both unusual and nice at this pricing point. It’s fantastic.

In summary, the Kobra’s X- and Y-axes are homing without the use of any form of endstop, whether physical, optical, or otherwise. Instead, it will steer the print head in certain directions and record the resistance when they approach their physical limits, cutting the motion and identifying its source.

It’s a feature of the stepper motor drivers in the printer (while not explicitly stated anywhere, we assume they are Trinamic TMC2209s.) Most low-cost printers won’t take advantage of these stepper motor drivers to their full capacity, but it’s a start.

Anycubic Kobra Review SINGLE Z-AXIS STEPPER MOTOR

We’re split on this one. Direct extrusion adds heft to the print head, increases the chance of resonance, and makes moving parts more difficult. A second motor to drive the Z-axis would make sense, but the Kobra avoids this step entirely. We saw no issues with only having a single motor when printing to the machine’s limits in the Z, but this could be something that comes with time and the printer “wearing in.”

Anycubic Kobra Review ADDITIONAL FEATURES

Belt tensioners: The Kobra’s belts can be manually tightened. Long-term upkeep is a plus.

Touchscreen display: Kobra’s touchscreen display is bright and snappy.

MicroSD cards are used to transfer prints to and from the printer. They’re clumsy and inconvenient.

Anycubic’s product documentation is quickly becoming one of the best in its price range. The included construction guide is simple, and a more extensive setup guide is included on the microSD card to assist new users in getting to know the system.

Is Anycubic Kobra Worth Buying?

all3dp’s Anycubic Kobra Review Conclusion

Here’s where the Anycubic Kobra threw us a curveball. We’d heard it was coming for a long time, and we thought it would be a new flagship before seeing any information or specifications.

The printer we received, on the other hand, is completely different. It’s little, cheap, and primarily made of plastic, but it’s packed with features and fun to use. The print quality impresses, even if our test device needed a little tuning out of the box to reign in some minor faults. Although some of the extruder components are lacking, it is still only $299.

And that’s the key: less than $300 for a direct extrusion printer with a removable, flexible bed and reliable automatic mesh bed leveling? That’s a fantastic deal.

If you don’t already own a 3D printer but have $300 to spend, the Kobra should be at the top of your list. Despite the fact that it may require a bit more effort from the user, it’s an improvement over the Ender 3 V2, the steadfast suggestion in this price bracket. We’re not sure how long those plastic components will hold up under severe use, but the beauty of them is that they’re easily changeable — an 8 out of 10. You’ll have to put in some effort, but the package is well worth it.

Anycubic Kobra Review Tech Specs

GENERAL SPECIFICATIONS

- Technology: Fused deposition modeling (FDM)

- Year: 2022

- Assembly: Semi-assembled

- Mechanical arrangement: Cartesian-XZ-head

- Manufacturer: Anycubic

3D PRINTER PROPERTIES

- Build volume: 222 x 222 x 252 mm

- Feeder system: Direct

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 260 ℃

- Max. heated bed temperature: 110 ℃

- Print bed material: PEI-coated spring steel sheet

- Frame: Aluminum

- Bed leveling: Automatic

- Display: 4.3-inch LCD touchscreen

- Connectivity: microSD, USB

- Print recovery: Yes

- Filament sensor: No

- Camera: No

MATERIALS

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Consumer materials (PLA, ABS, PETG, Flexibles)

SOFTWARE

- Recommended slicer: Cura 4.2.1 (provided)

- Operating system: Windows, Mac OSX, Linux

- File types: STL, OBJ, AMF

DIMENSIONS AND WEIGHT

- Frame dimensions: 486 x 430 x 486 mm

- Weight: 7 kg