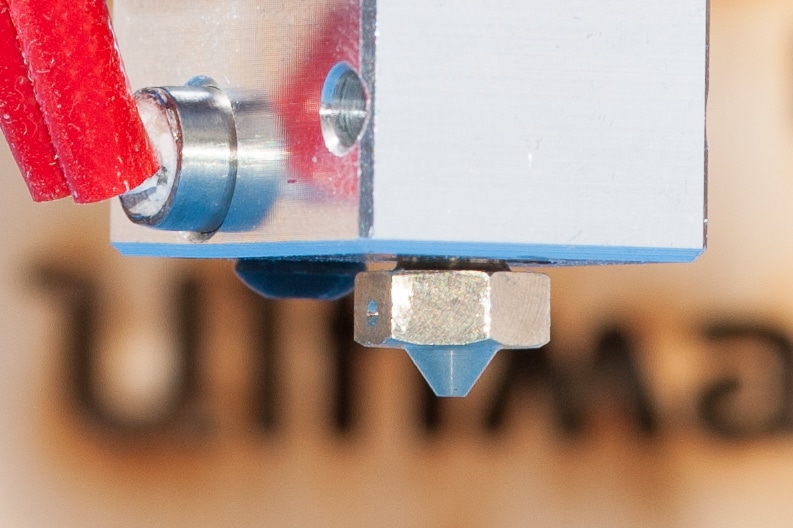

Plastic filament passes through the 3D printer nozzles before being deposited onto the print bed and forming the part. The nozzle has a big effect on the quality of your final print, the time it takes to print the model, and how much filament clogs, causing errors, for such a small component.

We’ll go into the various types of 3D printer nozzle materials, the benefits and drawbacks of each 3D printer nozzle size, and our top picks for the best 3D printer nozzles.

The nozzle size – diameter – and the materials the nozzles are made of are the two key factors people differ for use on their 3D printers. All of these factors have a major effect on part strength, print time, and the materials that can be printed.

If you’ve ever iced a cake, you’ll be familiar with how to use the nozzle. The nozzle of a 3D printer works similarly to that of an icing nozzle, but instead of squeezing sweet, sugary icing onto a muffin, plastic filament is melted and mechanically extruded via the nozzle.

Part 1: Size of 3D printer nozzles

The normal nozzle diameter for 3D printers is 0.4mm. The smallest nozzles start at about 0.1mm and sizes as large as 1.2mm or even 1.4mm are available, but the most widely used nozzles are between 0.2mm and 0.8mm.

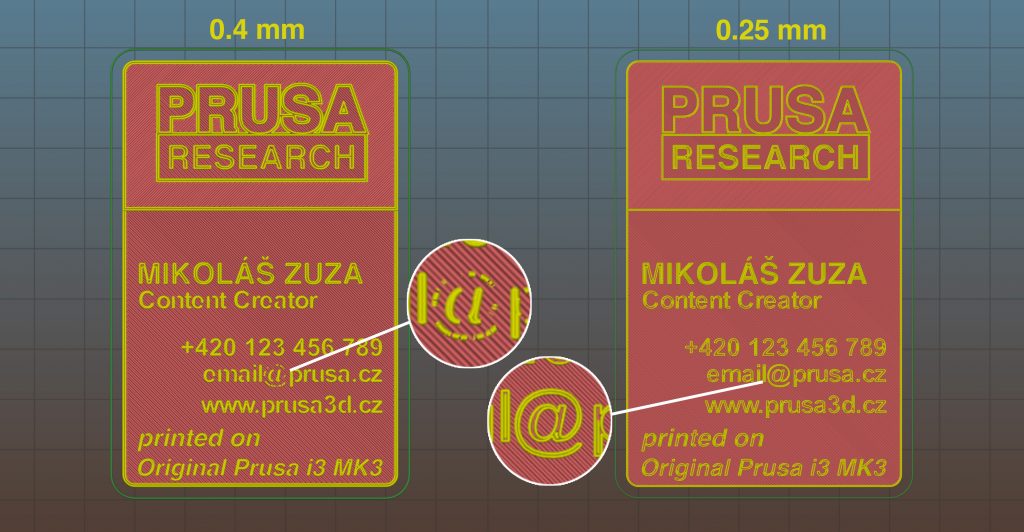

Using a large or small 3D printer nozzle has advantages and disadvantages. To summarize, a larger nozzle may extrude more filament at once, resulting in faster printing, while a smaller nozzle may print more complex and detailed information.

When you use a big nozzle size, like a 0.8mm nozzle, the pieces become more rough-textured, and the ridges that denote each layer become more visible. However, even with 10% infill, these sections are very solid and print easily.

The Benefits of a Large 3D Printer Nozzle

Faster printing: Larger 3D printer nozzles deposit more filament at once, allowing prints to be completed faster. A 0.8mm nozzle would print the same component approximately 4x faster than a 0.4mm nozzle – these are exponential speed changes, not incremental gains.

Less risk of filament clogging: Larger nozzles decrease the chance of filament clogging, and hence the chance of a print failing. This is because smaller nozzles have a smaller surface area to clog and therefore have a higher risk of doing so, while larger nozzles have a larger area to cover. Since wide nozzles print faster, there is a smaller window of time for the print to fail.

As a result, whether you’re using a 0.2mm or 0.15mm 3D printer nozzle, using high-quality 3D printer filament is critical to avoid clogging. Larger nozzle sizes (of about 0.5mm+) are needed for filaments such as wood- or metal-filled filaments, as smaller sizes clog much more frequently.

Better for rapid prototyping: When the aim is to quickly produce a rough, solid prototype, a large nozzle size is preferable. Because it requires fewer layers to print the component. If you sell 3D printing services and want to manufacture more parts or prototypes. And your clients don’t care about intricate precision. Increasing nozzle size is a very profitable decision.

The Benefits of a Small 3D Printer Nozzle

More precise: Smaller nozzles, on the other hand, are more accurate and capable of printing finer details than larger nozzles. This is critical when 3D printing miniatures and other complex parts, such as jewelry.

Another benefit of using a smaller 3D printer nozzle is that it can provide higher quality overhangs and print supports that are possible to separate in post-processing. These supports are easier to remove because 3D slicer programs can create more precise and detailed supports that use less filament and are therefore more easily broken off.

After all, if your 3D printer is incapable of producing these extremely precise layer heights and resolution, using a tiny nozzle would have little effect on the quality of your prints. However, since even low-cost 3D printers now deliver 50-micron precision, using a smaller nozzle diameter for precision is a better option.

Maximum layer heights recommended for each nozzle size

The absolute maximum layer height you can print is 80 percent of the diameter of your 3D printer’s nozzle, according to a general rule. This is the most severe number, and it is usually advised to keep it to 50 percent or less.

Based on this principle, the maximum layer height you can print with a regular 0.4mm nozzle is 0.32mm, while 0.2mm or even 0.1mm is preferred.

Part 2: Nozzle Content for 3D Printers

Brass is the basic nozzles for desktop 3D printers. They’re inexpensive, effectively conduct heat from the 3D printer’s heater block to melt and deposit filament, and they’re even compatible with stronger filaments like Nylon and PETG, as well as PLA and ABS.

Brass Nozzles for 3D Printers

Brass nozzles, on the other hand, do not function well with abrasive filaments. Other nozzle materials, such as stainless steel, reinforced steel, or even ruby-tipped nozzles, are used instead for these filaments, such as NylonX or wood- or metal-filled filaments.

3D Printer Nozzles Made of Stainless Steel and Reinforced Steel

Stainless steel 3D printer nozzles operate well with these filaments, but they wear out quicker and need to be replaced more often than hardened steel 3D printer nozzles. With moderate printer use, these treated steel nozzles are more stable and can last much longer.

Ruby nozzles for 3D Printers

Ruby-tipped 3D printer nozzles are the pinnacle of 3D printer nozzles. They have the same nozzle shape as before, but instead of the previous metal, there is a tiny ruby on the nozzle tip. Rubies are totally abrasion-resistant and will never wear out, regardless of how much you print with them.

However, they are much more expensive, and some people choose to pay a big upfront cost for a ruby nozzle that would not need to be replaced. The nozzle is not bulletproof because the non-ruby component (made of brass or other material) will wear down.

Overall, it is widely known that you would not see a positive ROI from a ruby-tipped filament unless you are printing industrial quantities of abrasive materials – at least several kilos per week. Most manufacturers recommend purchasing reinforced steel 3D printer nozzles, which are less expensive and do not need to be replaced as often, saving you money in the long run. Ruby nozzles, on the other hand, are typically very good and provide another premium choice for your printer’s nozzle.

Final Thoughts

If we had to choose only one nozzle to replace the 0.4mm, we’d go for the 0.6mm as an option. It has slightly shorter printing times, but it also allows for fairly accurate models to be printed. If you often print small models with text, jewelry, or logos, the 0.25mm a nozzle is a good option. The 1mm version has a small use, but it’s still a lot of fun to play with.

Let us know in the comments below or on our Facebook page to let us know your ideas, and we would appreciate seeing pictures of your works of art!