In recent years, 3D printing has made significant advancements. It has evolved from a technology mainly used for prototyping to one now being utilized to produce genuine things. Researchers are currently investigating the creation of 3D printed organs for humans. This might transform the medical industry!

Researchers are employing 3D printing technology, which has advanced significantly in recent years, to create innovative medical equipment that would otherwise be hard to manufacture. Human ears, tracheas, bones, and other organs have all been successfully printed in three dimensions by researchers at the Wake Forest Institute for Regenerative Medicine. For transplant patients, this also applies to organs made to order.

In this post, we’ll look at how this technology might be used to produce organs for human transplants. We’ll also talk about how this technology affects ethics.

The Future of Medical Technology

Though it hasn’t quite reached the stage where most homes have access, 3D printing is finally becoming popular in the industrial sense. However, the technology is ready to expand on its current adoption. Into a wide range of fields we don’t typically connect with. One of them is the medical industry, which will probably increase its usage of 3D printing as it grows more and more versatile. In the past ten years, medical printing has gained popularity as researchers explore uses for the technology beyond just reproducing simple bones and organs. Several pharmaceutical firms have been developing tablets that can

Imagine for a moment a situation in which patients do not need to wait for an organ transplant. This is a possibility thanks to 3D printing.

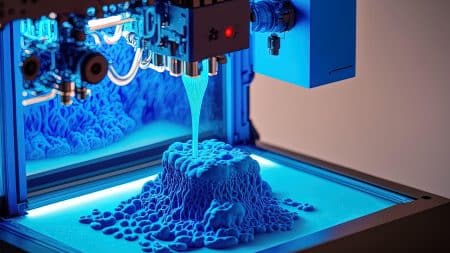

In bioprinting, a 3D printer—more precisely, a bioprinter—uses a “bio-ink” made of thousands of living cells to produce human tissue. This method could be used by medical researchers to create organ transplants. Theoretically, the procedure would begin with removing tissue cultures from a patient, then printing these cultures into the shape of the desired organ, and finally, the transplantation of the organ into the patient. The likelihood of the body rejecting the organ is significantly decreased because it is created from the patient’s genetic material.

Even though it sounds exciting, 3D printed organ transplants are still a ways off, but 3D printing is currently being used in the medical industry.

This technology is already being extensively used in the medical industry, and prosthetics are one of the critical areas where it is reshaping things.

Organizations like Enable have been essential. Organizations are now printing children’s splints, feet, and legs. Customized prosthetics are becoming increasingly popular because of their affordability and toughness. A personalized prosthetic may be printed quickly once the user’s dimensions are entered, thanks to 3D printing and computer modeling. In the past, individual pieces had to be hand-assembled based on the user’s measurements. This enables quick, customized goods to be manufactured on-site. Despite the modeling’s nearly limitless customizability, these 3D printed prosthetics are only a tiny portion of the price of more conventional versions. The 3D-printed prosthetic created by Ivan Owen, who owns the business “Shackleton Gears” in Washington State, is one instance of a successful one.

Most hearing aids sold today are 3D printed using stereolithography technology, which has many advantages. Multi-jetting enables the simultaneous use of a hard inner and a soft coated exterior for comfort. In contrast, stereolithography does not permit using more than one material for the device’s construction.

Custom-made aligners from Invisalign are an example of how 3D printing is used in dentistry. Because of its tailored fit, it can exert just the proper amount of pressure on the teeth to move them in the desired direction.

Though 3D printing has also been used to create implants, surgical instruments, and other gadgets used in hospitals and doctor’s offices in addition to these valuable goods. Although it is not yet commonplace in the industry, it is growing more and more so.

New applications for 3D printing in medicine are being discovered daily. These applications will undoubtedly alter the way we currently view therapy.

3D Printed Organs Could Revolutionize the Field of Medicine3D Printing in Healthcare

The development of 3D printing is altering the way we view healthcare. We can now develop brand-new goods and services that were previously impractical. Personalized hearing aids, prosthetic limbs, and organ transplants fall under this category.

Because every person’s body is different, 3D printing excels in healthcare applications by offering personalized treatments. Researchers are quickly developing new 3D printing uses for healthcare, whether a cast made from a 3D scan of a child’s forearm, fresh tissue to treat an injury or entirely new organs produced with embedded vascular structure.

A computer-designed 3D model is manufactured into a three-dimensional object via the 3D printing technique, also known as additive manufacturing. There are numerous forms of 3D printing. They may be done using various basic materials, including plastics, metals, and human cells. You may create highly intricate shapes and designs by building up the material, often in layers, which is impossible with conventional production.

Surgeons can train on replicas of patient organs thanks to the capacity to personalize 3D printing in healthcare, increasing their success rates. Doctors can do more precise targeted medicine administration at the nanoscale.

3D Printed Organs Could Revolutionize the Field of Medicine

3D Printing in Dentistry

3D printing technology in the medical industry, including dentistry, has been around for more than 40 years. The possibilities and uses of 3D printing in dentistry have substantially evolved since its inception.

Dental professionals now have the opportunity to buy 3D printers and use this technology in their procedures. Dentistry experts who adopt this technique must comprehend the advantages of this technology and the various technical aspects that affect this equipment’s performance to make the best decision. In this post, we’ll examine the application of 3D printing in dentistry and discuss its advantages. We’ll also discuss the uses and possibilities of 3D printers and offer guidance on how to pick the ideal piece of equipment for your dental practice.

3D Printed Organs Could Revolutionize the Field of Medicine

3D Printing in Surgery

Surgery also makes use of 3D printing. A human skull replica was recently manufactured by a team from Harvard Medical School. The procedure to remove a tumor from a child’s brain was planned using this model.

Surgical interventions are currently depending more and more on 3D printing to develop and obtain a greater understanding of complex operations. While this is happening, AM is becoming more affordable and available, helping to test novel materials and adjust current procedures to the wide variety of opportunities available.

It goes without saying that additive manufacturing (AM), which is quite popular when it comes to new, creative medical components, has revolutionized the sectors of dentistry and orthodontics. Therefore, it makes sense that AM would eventually catch up to surgery, proving a significant advantage in areas like lowering costs, operating times, and built-in prosthetics.

Is it ethical to 3D print organs?

Manufacturing has undergone a transformation thanks to 3D printing, enabling companies to make complicated goods quickly and affordably. However, the production of human organs is a considerably more contentious application of 3D printing. Due to a lack of transplantable organs, there is already a black market where individuals are willing to pay exorbitant sums of money for a kidney or heart.

Some businesses have begun printing organs in three dimensions using stem cells. Then, those in need receive the transplanted organs. Critics contend that the technology is still in its infancy and that 3D-printed organs are inferior to natural ones. They are also concerned about the moral ramifications of laboratory organ growth. However, backers

Can doctors 3D print organs?

Even while 3D printing technology has advanced significantly in recent years, we are still a long way from being able to create healthy human organs. However, numerous businesses and research groups are focusing on this issue, and it won’t be long before we figure out the solution. 3D printing is already being utilized to successfully construct patient implants and prosthetics.

Therefore, it is evident that 3D printing is already transforming medicine, even though we may not yet be able to create functioning organs. It’s conceivable that the medical industry will make even more incredible advancements when technology develops further.

3D Printed Organs Could Revolutionize the Field of Medicine

Conclusion

There are various questions concerning whether or not 3D printing of organs will help to address the dilemma of organ scarcity. Critics are concerned about the moral ramifications of growing living human tissue outside of the body and the timeline for scientists using bioprinting to produce permanent, functional organs. Supporters of 3D printed organs point out that because of its ability to create more complicated structures, better options for prosthesis and implantation in people who require them.

There are several other ways that 3D printing has already revolutionized medicine, including the on-demand production of implants and prosthetics like hearing aids and hip replacements, allowing patients to regain mobility without waiting years for an organ transplant.

How do you feel? Do you think it would be feasible to produce organs for transplant via bioprinting? Or are you worried about the ethics of this technology? Let us know in the comments below!