Table of Contents

Discover what happens when your 3D printer runs out of filament during a print job, how to prevent it, and how to recover when it occurs.

The Perils of Running Out of Filament

Imagine working on a critical project that needs a 3D-printed part, and you’re running against time. You set the print job to run overnight, only to find the next morning that your 3D printer has run out of filament. The result? An incomplete print and a waste of precious time.

Running out of filament during a print job is a common challenge faced by many 3D printing enthusiasts, especially when printing large or complex models. In this article, we’ll explore what happens when your 3D printer runs out of filament, how to prevent it, and how to recover when it occurs.

What Happens When Your Printer Runs Out of Filament?

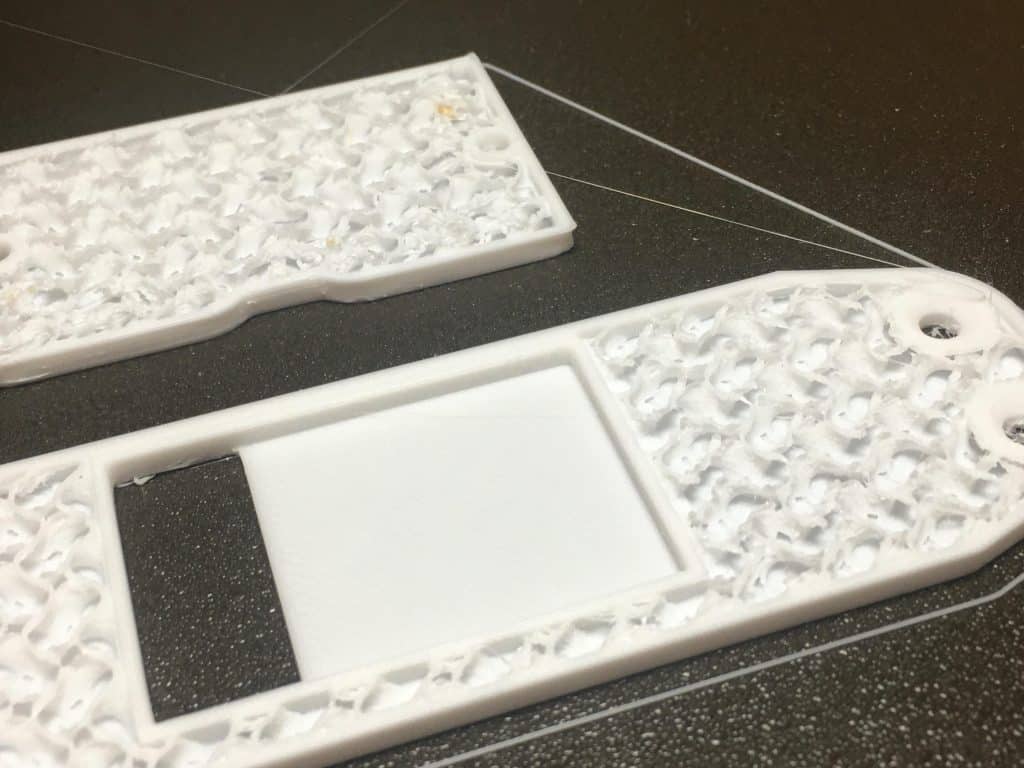

When your 3D printer runs out of filament, the print head continues to move along the predetermined path, but no material is extruded. This scenario results in an incomplete print with gaps or missing layers, making it unsuitable for use.

If you’re lucky, you might notice the filament shortage before the print is entirely ruined, allowing you to pause the print job and reload the filament. However, even then, you risk introducing inconsistencies or weak points in the final print, as the new filament may not adhere perfectly to the previously printed layers.

Preventing Filament Runout Mishaps

At this point, you might be wondering how to prevent filament runout in the first place. A stitch in time saves nine, right? Well, here are some tips to help you avoid running out of filament and to keep your 3D printing projects running smoothly.

- Monitor filament usage: Keep a close eye on your filament spool while printing. Make sure you have enough material to complete your project before starting, or be prepared to swap out the spool if needed.

- Use a filament runout sensor: Some 3D printers come with a built-in filament runout sensor. This helpful feature alerts you when your filament is about to run out and pauses the print automatically, allowing you to replace the spool and resume printing without issue. If your printer doesn’t have this feature, consider installing an aftermarket sensor.

- Choose the right spool size: If you’re working on a large project, consider using a larger spool to reduce the risk of running out of filament during the print. However, be aware that not all 3D printers can accommodate larger spools, so check your printer’s specifications first.

- Weigh your filament: Before starting a print, weigh your filament spool to estimate the amount of material you have left. Many slicing software applications can provide an estimate of the amount of filament required for a print job, which can help you determine if you have enough material to complete the project.

- Keep extra spools on hand: It’s always a good idea to have backup filament spools available, especially if you frequently print large or complex projects. This ensures you’ll be ready to swap out the spool if you run out of material unexpectedly.

By following these tips, you’ll be better prepared to handle filament runout and keep your 3D printing projects on track.

Recovering from Filament Run-Out

There may be times when filament runout catches you off guard, and your print is paused midway. Don’t worry! It’s possible to recover from this situation and resume your print successfully. Here’s a step-by-step guide to help you get back on track:

- Pause the print: As soon as you notice the filament runout, pause your print using the control panel on your 3D printer or your preferred slicing software. This will prevent any further movement and ensure your print head stays in place.

- Replace the filament: Remove the remaining filament from the extruder and replace it with a new spool. Make sure to use the same type and color of filament to ensure consistency in the final print. If necessary, trim the end of the new filament at a 45-degree angle to facilitate easier loading.

- Prime the extruder: Before resuming the print, it’s essential to prime the extruder to remove any air bubbles and ensure smooth extrusion. To do this, manually extrude a small amount of filament through the nozzle until you see a consistent flow. You can use the control panel on your 3D printer or your slicing software to accomplish this.

- Clean the nozzle: Use a clean cloth or paper towel to gently wipe away any excess filament from the nozzle. This helps prevent blobs and stringing when the print resumes.

- Adjust the Z-axis: Depending on your 3D printer, you may need to adjust the Z-axis to ensure the print head is at the correct height before resuming. Check your printer’s documentation for specific instructions on how to do this.

- Resume the print: Once everything is set up, use the control panel on your 3D printer or your slicing software to resume the print from where it left off. Keep a close eye on the print for the first few layers to ensure proper adhesion and that there are no issues with the new filament.

By following these steps, you can recover from filament runout and resume your print without losing any progress. This will save you time, filament, and frustration, allowing you to continue creating amazing 3D printed projects.

FAQ Section

Can I continue a print after the filament runs out?

Yes, it’s possible to continue a print after running out of filament. However, the process can be tricky and may require manual intervention or the use of a filament runout sensor.

What happens if my 3D printer runs out of filament during a print?

If your 3D printer runs out of filament during a print, the extruder will continue to move, but no material will be deposited. This can result in an incomplete print, with layers missing or the print detached from the print bed.

How can I tell if my 3D printer is about to run out of filament?

You can monitor your filament spool visually, weigh the spool before starting a print, or use a filament runout sensor if your printer is equipped with one.

Can I mix different types of filament in a single print?

Yes, you can mix different types of filament in a single print, but it’s essential to ensure that they have similar printing temperatures and are compatible with each other. Mixing incompatible filaments may cause issues with the print quality or the adhesion between layers

Conclusion

Running out of filament mid-print can be frustrating, but it doesn’t have to spell disaster for your 3D printing project. By understanding the potential issues and using the tips and tricks provided in this article, you can overcome filament runouts and keep your prints going strong. Don’t forget to check out our other articles on how to connect your Ender 3 to your PC, the top resin 3D printers of 2023, and how to clean your 3D printer nozzle for more expert advice on making the most of your 3D printing experience.

Remember, preparation is vital when it comes to avoiding filament runout mishaps. By monitoring your filament usage, employing a filament runout sensor, choosing the right spool size, weighing your filament, and keeping extra spools on hand, you’ll be ready to tackle any print job confidently.

As 3D printing technology continues to advance, new solutions and best practices will undoubtedly emerge to help users manage their filament supply more effectively.

We hope you found this article helpful in managing your 3D printing filament supply and avoiding the dreaded filament runout. If you’d like to stay up-to-date with the latest 3D printing tips, tricks, and innovations, be sure to subscribe to our newsletter and follow us on social media.

We’d also love to hear about your own experiences and strategies for managing filament runout. Share your thoughts and insights in the comments section below, and don’t forget to join our thriving community of 3D printing enthusiasts on our Facebook page. Sign up for our free weekly newsletter to receive all the latest 3D printing info in your email!

Together, we can continue learning, innovating, and creating amazing 3D printed projects. Let’s keep the conversation going and the filament flowing!